2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:38

There are different types of steel, each with its own pros and cons. Therefore, you need to know what metal to buy this or that product so that it lasts as long as possible.

Universal steels

The characteristics of a steel object are its geometry, but to a greater extent the structure of the metal, which, in turn, depends on its composition and the necessary thermal, chemical and mechanical processing. It is the combination of these criteria that explains such a huge number of steel grades and finished products. Since there are different priorities for the characteristics of metal products (sometimes only strength is needed, and sometimes only ductility), steel is initially selected according to its chemical composition, and receives its final properties through further processing.

Combination of qualities

Processing modes are selected as accurately as possible for each part, and if necessary, even a small part of it. They depend, as a rule, on what place the element occupies in the structure and what loads it experiences (friction, dynamic, tension, compression). Based on this, goals are also set: to achieve firmness,plasticity or a combination of these qualities. It is possible to obtain the same hardness, strength, ductility for steels with different chemical composition, but at the same time they may give unsatisfactory results according to other criteria. But the same metal grade can be used for parts for different purposes. So, for a pirmer, steel 95x18 can be the basis for the manufacture of various parts, but with the same requirements for tensile strength and hardness. These items and parts can be heterogeneous: bushings, axles, bearings, but steel shows its best characteristics in the manufacture of hunting knives.

Properties and features

95X18 - one of the best and most practical steels used for the manufacture of knives with particularly strong performance. As a rule, these are products for hunters. People who give their preference to knives from this brand do not make their choice by chance. Even without delving into the intricacies of metallurgy, they help to get to know knives made of 95x18 steel better, reviews of other users, from which you can understand a lot. Namely: this is the most optimal material for this kind of products.

The chemical composition and properties of this alloy were discovered not so long ago. But its growing popularity says a lot about the high performance of this material. Mostly professional companies work with this steel, since it is very capricious, it is characterized by such defects as overburning or insufficient tempering. This requires people with a good knowledge of the steel business and modern precision equipment, which canonly a company professionally engaged in the production of knives or other metal products.

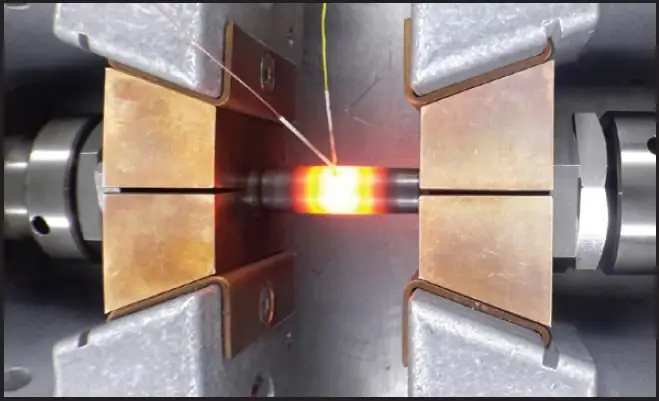

Forging treatment

The presence of chromium in its chemical composition pushes high-strength steel into a series of corrosion-resistant or stainless. In addition, steel 95x18 is intended for forging. For any metal structure, this procedure is a “treatment” for many diseases, the most common of which are microcracks, filling pores with harmful elements of hydrogen, oxygen, and, of course, vacancies (a place not occupied by an atom that forms a cavity). In addition to "diseases", forging helps to get rid of chemical and dendritic segregation, to "stack" all molecules more tightly. With such a rigid structuring, the metal grain is refined. This allows you to increase ductility without reducing strength. After that, it has steel 95x18 characteristics that can withstand heavy loads even in bending.

The shape of the knife is just as important

Design features of cutting products complement and increase functionality. They properly distribute the load and make the use of the knife easy and comfortable. In the manufacture of the blade, great importance is attached to the shape, size, method of sharpening the edge and the method of attaching the handle. Each of these items has more detailed fixtures. They increase convenience and enhance the artistic value of the product. There is a direct dependence on the thickness of the blade and the quality of cutting. The thinner the blade, the better they performsmall work.

Production technology

Steel 95x18, knives from which are obtained with a very strong and wear-resistant edge, must go through several stages of processing. The work begins with obtaining a small casting, which is annealed before forging (the workpiece is heated to a temperature of 885-920 degrees Celsius and held for 1-2 hours). It is very important not to burn the metal here. If this happens, then the workpiece is no longer subject to further processing. Only after such exposure is the olive ready for forging. A plate of the desired size is formed from it. Plus allowances for machining (sharpening, grinding) are given. After forging is completed, the workpiece is rapidly cooled in engine oil. This is called hardening. At this stage, the steel has a very high brittleness, and if it is not removed, then the metal will crumble like glass with a slight impact. Maybe sometimes there is the work of an inexperienced craftsman, but basically 95x18 steel receives positive reviews from consumers. The tempering procedure is heating the workpiece, but to lower temperatures - only up to 200-300 degrees Celsius.

Edging

The cutting edge of the knife gets its shape in two passes. The first run allows you to get only preliminary dimensions, the second - more accurate. Immediately after the first tempering, final machining is carried out. The blade on the machine is ground to the desired size. Steel 95x18, the heat treatment of which takes place in four stages, takes on the final properties after the second tempering, in whichall stresses are removed - and the metal becomes as ductile as possible. To do this, the finished blade is kept at a temperature of 150 degrees for 1-2 hours. Cooling takes place in air. To decorate the blade with peculiar patterns, acid etching can be carried out.

Knife care

Despite its hardness and strength, steel is subject to slow degradation. Of course, this process lasts more than a dozen or even a hundred years, but it can be reduced to a minimum by accelerating it with the wrong care.

Steel 95x18, having a high content of chromium in its composition, is distinguished by its corrosion resistance, which increases the service life. Products made from it also have this feature, but nevertheless, both the steel itself and the design features of the knife require careful treatment.

- Mechanical loads. The knife must not be used for other purposes. Loads calculated on the handle, edge and blade can destroy many materials, including very strong ones (wood, wire, etc.), but the sharpening and curvature of the blade will suffer first of all.

- Moisture, dampness, acidic environment. Despite the fact that steel 95x18 is corrosion resistant, prolonged contact with a solution with a high s alt content adversely affects the surface. Just like staying in a humid place for a long time.

The technology of manufacturing knives, like other steel items, is subject to GOST, technological maps and instructions. This type of steel is highly valued not only in Russia. It also easily competes with foreign brands and surpasses many of them in terms of basic parameters. But, despite this, the products of each master have their own differences. This suggests that working with metal is not only a technological process, but first of all it is a vocation.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Heat resistance and heat resistance are important characteristics of steels

Ordinary structural steels, when heated, abruptly change their mechanical and physical properties, begin to actively oxidize and form scale, which is completely unacceptable and creates a threat of failure of the entire assembly, and possibly a serious accident. To work at elevated temperatures, materials engineers, with the help of metallurgists, created a number of special steels and alloys. This article gives a brief description of them

Heat-resistant alloys. Special steels and alloys. Production and use of heat-resistant alloys

Modern industry cannot be imagined without such material as steel. We encounter it at almost every turn. By introducing various chemical elements into its composition, it is possible to significantly improve the mechanical and operational properties

Heat treatment of steel is an important process in the production of metals

Heat treatment of steel gives any steel product the desired properties. This process is an important step in the production of iron alloy

Heat treatment of alloys. Types of heat treatment

Heat treatment of alloys is an integral part of the production process of ferrous and non-ferrous metallurgy. As a result of this procedure, metals are able to change their characteristics to the required values. In this article, we will consider the main types of heat treatment used in modern industry