2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

Heat treatment of steel is an important process in the production of iron alloy, which can improve its useful properties. Today, this procedure is used to transform the natural characteristics of most metal products.

Heat treatment of steel involves the sequential execution of three stages:

- Heating the iron alloy to the desired temperature.

- Steel holding for a certain time.

- Cooling.

What happens to the iron alloy with this procedure?

Heat treatment consists of the following steps:

1. Annealing. This process is mainly used for casting, rolling and forging. This procedure is necessary to reduce hardness or reduce internal stresses that are created in welded products. In addition, annealing is used to prepare the metal structure for subsequent thermal processing in order to improve its heterogeneity. This method includes heat treatment of steel 45, 45X, 40XC, 40XH and other grades of iron alloy.

2. Normalization. This procedure differs from the previous process in the nature of the passagecooling stage. The last step is carried out after exposure of the details. In this case, special attention is paid to the set temperature. In this case, the steel is obtained with a slight, but higher hardness. The structure of these products is fine-grained. Thus, steel normalization is necessary to correct the composition of the weld, as well as to obtain the desired configuration.

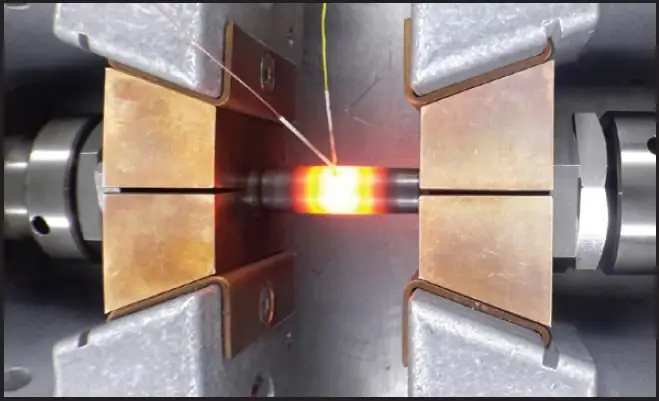

3. hardening. This steel processing step is applied to forgings, castings, stampings, and parts machined to improve strength, hardness, corrosion resistance, wear resistance, and other important characteristics. This process is the heating of an iron alloy to a temperature above, or within its transformation. Exposure of steel at such a thermal indicator, as well as subsequent cooling, is carried out, as a rule, at a slightly higher speed. For this, aqueous solutions of NaOH s alts, oils, and air are most often used. So, for example, heat treatment of steel 40x at this stage is carried out in oil. Quite rarely, parts of large dimensions are subjected to quenching in water with immediate subsequent low tempering. Often, products made from this brand of iron alloy go through this stage by heating high-frequency currents. The result is a high solid surface.

4. Vacation. This procedure consists in heating hardened steel to a certain temperature. Next, the metal undergoes exposure, as well as cooling. The last step is usually carried out in the air.

5. Aging. This stage consists in keeping the iron alloy with a metastable structure for some long time. The temperature should not be lower than room temperature. This procedure allows the metal structure to partially transition to a more stable state by changing its mechanical and physical properties.

6. Cold processing. This step is a continuation of the quench cooling that was interrupted at room temperature. This indicator for the metal is not a critical level.

Iron alloy applications

Because the steel heat treatment procedure can significantly improve the performance of parts made from various grades of iron alloy, it is in great demand in all industries. Mechanical engineering, aircraft building, tank building, and the production of reinforced concrete products are no exception. Products that have undergone heat treatment can be operated under conditions of dynamic increased load and vibration. In addition, such iron alloys are used in the construction of skyscrapers, factories and bridges.

Recommended:

Heat resistance and heat resistance are important characteristics of steels

Ordinary structural steels, when heated, abruptly change their mechanical and physical properties, begin to actively oxidize and form scale, which is completely unacceptable and creates a threat of failure of the entire assembly, and possibly a serious accident. To work at elevated temperatures, materials engineers, with the help of metallurgists, created a number of special steels and alloys. This article gives a brief description of them

Heat-resistant alloys. Special steels and alloys. Production and use of heat-resistant alloys

Modern industry cannot be imagined without such material as steel. We encounter it at almost every turn. By introducing various chemical elements into its composition, it is possible to significantly improve the mechanical and operational properties

Heat treatment of alloys. Types of heat treatment

Heat treatment of alloys is an integral part of the production process of ferrous and non-ferrous metallurgy. As a result of this procedure, metals are able to change their characteristics to the required values. In this article, we will consider the main types of heat treatment used in modern industry

Steel 95x18: characteristics, reviews, heat treatment and knife making

What kind of steel are quality knives made of? How to follow them correctly? What properties do these products have? Read about this (and more) in our article

Steel annealing as a type of heat treatment. Metal Technology

Creating new materials and controlling their properties is the art of metal technology. One of its tools is heat treatment. This knowledge allows you to change the characteristics, and, accordingly, the scope of the use of alloys. Steel annealing is a widely used option for eliminating manufacturing defects in products, increasing their strength and reliability