2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Giving traditional materials special characteristics has long been a common practice. Products with improved properties of chemical protection, increased heat resistance and hardness are used in energy, mechanical engineering, production of building materials and other areas. At the same time, narrow areas of application of the same fire-resistant products are not left without attention. So, in medicine, borosilicate glass is widely used, the dishes from which are easy to use and have a considerable range of protective properties.

Glass composition

The technical and physical qualities of materials are determined by two factors - the processing technique in the production process and the components of the primary element base. By and large, this glass is a representative of a group of conventional silicate materials, which are based on oxides. This is a basic list of components, including sodium carbonate, quartz sand and calcium oxide, that is, limestone. At the same time, borosilicate glass is distinguished by the presence in the composition of one more element, which largely determined the non-standard qualities of the structure. Boron oxide is added to the general silicate composition, which ensures the resistance of glass totemperature fluctuations. Of course, the composition of modern glasses is not limited to this, since technologists modify sets of elements, focusing on specific requirements for end products.

Glass technology

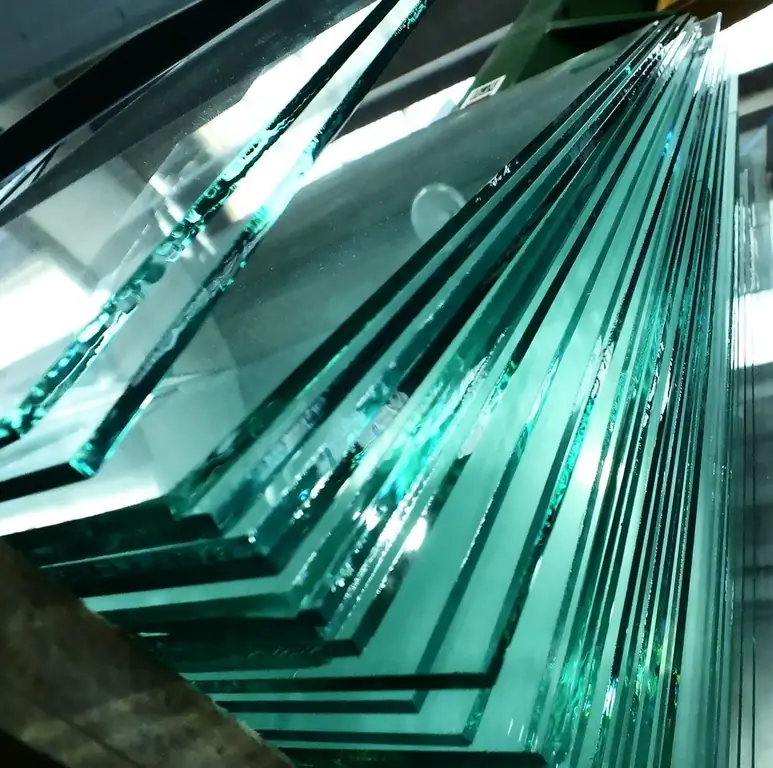

In general, the manufacturing technique of borosilicate material is similar to the manufacturing technology of conventional glass. In the process of cooking the main melt, furnace units with a temperature of more than 1300ºC are used. The liquid mass is molded on special metal panels. According to the float process technique, sheet borosilicate glass is produced with specified dimensions. The peculiarity of this method is that the resulting sheets are not cut and not corrected at all, but are used in the finished form by the end user.

From such glasses, double-glazed windows, doors, and in some cases, fireproof partitions are further assembled. A considerable proportion of industries involved in the production of such glasses is focused on the manufacture of finished dishes. These can be test tubes, vessels, bowls and other items used in medicine and technical support of research centers. On special equipment, mechanical cutting and polishing of ingots is performed, from which laboratory glassware in various forms is subsequently obtained. Actually, the main difference between the manufacture of this material and conventional silicate analogues is the organization of the workflow at a higher temperature.

Key Featuresglass

Glass of this type is beneficial in many properties and performance characteristics. First of all, this is a wide temperature range of the environment in which glass can be used. As standard, the material withstands frost down to -80ºC and heat up to 525ºC. From the point of view of operation in laboratory conditions, resistance to chemical influences comes first. It is these qualities that are endowed with a medical test tube. Borosilicate glass with its inertness is enough for the user to reliably protect the contents from acids, s alts, alkalis and organic compounds. The mechanical stability of this material is also noted. Since the density factor of the borosilicate backing is higher than that of silicate glasses, it is better protected from the risk of physical damage. In addition, strong thermal effects do not destroy the glass surface into small fragments, but burst the panels, which form blunt and safe edges.

Sizes and format of issue

Specialized glassware is usually produced under the order of laboratories and medical enterprises. However, the production of sheet materials provides for some release standards. In particular, the thickness of the glass panel may be 6-12 mm. In this case, the error usually does not exceed 0.3 mm. The maximum format in which sheet heat-resistant glass is produced is represented by a size of 150x300 cm. But, again, by special order, many enterprises, if technologically possible, expand these parametersmanufacturing. As for the minimum values, it is customary to consider the 10x10 cm format as the smallest unit of production of such glass.

Application areas

As already noted, the characteristics of the material are best suited for use in laboratories, in equipping medical offices, etc. For such purposes, manufacturers produce flasks, vessels, test tubes and other products. The borosilicate glass vacuum tube, in addition to special physical characteristics, also has a design feature. Although outwardly it may seem that this is one tube, in fact there are two of them and they form a vacuum. Sheet glass of this type also finds its application. It is commonly used as partitions, in optical technology and when equipping rooms with protective barriers.

Fireproof borosilicate glass

The qualities of fire resistance are especially highly valued - one of the key characteristics of borosilicate material. Manufacturers produce special panels for glazing and door and window panels with enhanced protective qualities. At the same time, for example, spider glazing is distinguished not only by fire-resistant properties, but also by mechanical resistance. In a complete set of standard plastic window systems, heat-resistant glass is also used, which provides thermal protection. Fire-resistant materials for decorating ceiling and floor surfaces are also gaining popularity.

Restrictions on the use of glass

Despite a wide range of favorable technical and operational properties,borosilicate products have some restrictions on their use. As for interaction with an open flame, the material is able to hold fire for no more than an hour. This nuance does not allow the use of such glass in rooms with increased requirements for fire safety. There are also limitations for other areas of application. In particular, laboratory glassware does not withstand contact with hydrofluoric and hydrofluoric acids. Caustic alkali, the effect of which is reinforced by high temperature, also negatively affects test tubes with flasks. By itself, extreme temperature conditions do not destroy the glass, but sudden changes do not allow the material to adapt the structure in a timely manner.

Conclusion

Borosilicate glass products should not be considered as a special material for targeted chemical and fire protection. We can say that these are secondary and even auxiliary characteristics that traditional products are endowed with to increase practicality. Nevertheless, borosilicate glass, in addition to protective qualities, retains such properties as transparency and light transmission. Therefore, the combination of mechanical resistance, fire resistance and translucency allows us to consider the material as unique. At least that is what laboratory glassware is, which, in addition to the above characteristics, also has optimal inertness.

Recommended:

How to make glass? Glass production technology. glass products

Glass is familiar to everyone. But the process of making it is extremely exciting. Each stage is important and affects the quality of the final product. The basis is sand, soda, lime. The process is almost entirely automated. Surprisingly, glass can even be made at home

Glass sandblasting: glass processing description, equipment, application, photo

Among the numerous variations of interior decoration, sandblasting of a glass or mirror surface occupies a special place. This technology involves exposing the canvas to sand or other abrasive with a jet of compressed air released under high pressure. As a result, the surface changes and becomes matte, rough, velvety or painted with patterns. In the article we will consider what is sandblasting glass

Flow methods of production organization: parameters, characteristics and standards. The need for this method in production

Today, in-line production is the most progressive form of organization of the production system. Optimal speed of work, minimum labor intensity and maximum quality of production - this is not a complete list of the advantages of the method under consideration

Grinding car glass. How to grind glass

The article is devoted to glass grinding. The grinding procedure, its tasks, technique, materials, etc. are considered

Glass factories in Russia. glass industry

The glass industry occupies an important place in the country's economy. Glass factories in Russia operate in almost every region. Window panes and portholes, bottles and dishes, household and interior items - without these items it is impossible to imagine modern civilization