2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Very often there is a need to cut large sheets of metal into pieces, break off pieces from them, cut grooves and channels, remove hard crusts, etc. All of these procedures use different methods.

How to cut metal at home

Home metal cutting is done with a vice, a hammer and a chisel. The last tool consists of three parts - percussion, middle and working. The working part is made in the form of a wedge, the master holds the middle tool, the impact part has a rounded end and tapers upwards.

For the production of chisels, carbon steel is used. Before the start of cutting, risks are applied to the workpiece at the place of the future cut. Then the sheet is inserted into the vise so that the marks are visible. The first blow is applied with a chisel horizontally, all subsequent ones - at an angle of 25-30 degrees. Cutting sheet metal is a rather complicated and time-consuming procedure, so the method described above is only suitable for processing small batches of material. On an industrial scale, more thanperfect automated methods.

Cutting large quantities of metal

Often in small workshops, and sometimes in enterprises, a chipping pneumatic hammer is used to cut metal sheets. The worker holds it with both hands, directing the chisel exactly along the intended cutting line. Cutting metal in this way is less labor intensive and faster than manual cutting. The pneumatic hammer can operate both from a conventional network and from a compressor.

Cutting metal sheets using a guillotine

In large enterprises, if there is a need to process very large batches of metal, a special tool is used that significantly reduces the operation time, often making this process fully automated. This is a guillotine. Cutting metal with a guillotine is carried out immediately along the entire length of the sheet. Before starting work, the metal workpiece is fixed on the horizontal support of the device using a beam. Then the guillotine knife is brought to the place of cutting. The sheet is cut with one movement of the knife. In this case, the cut is very even.

Advantages and disadvantages of the guillotine method

Cutting metal with a guillotine has many advantages, such as:

-

cutting metal with a guillotine high speed operation;

- slicing accuracy;

- high quality (the seam does not require further processing);

- economical (metal loss is minimal).

However, this method has some disadvantages:

- workpiece size is limited;

- steel with a high content of silicon, titanium and chromium cannot be cut in this way;

- comparatively high cutting cost;

- narrow range of metal thickness;

- limitation of work in terms of temperature conditions (the indicator depends on the technical characteristics of a particular model of the guillotine).

In addition to electric guillotines, manual ones are often used in enterprises. Their convenience lies primarily in the fact that such tools can be used in any conditions, even where there is no electricity.

Cutting metal is a very complex process that requires attention and accuracy. Using modern devices designed for this purpose, you can significantly reduce labor costs, speed up the processing process and improve the quality of the result.

Recommended:

Metal band saw. Metal cutting machine

Metal band saw is a high-performance equipment that is responsible for a variety of functions, such as cutting metals and cutting a variety of strong and high-strength materials

Types of metal cutting: an overview of modern technologies and equipment

One of the most common metalworking operations is cutting. It is a technological process during which a sheet or billet is divided into parts of the desired format. Modern types of metal cutting allow this operation to be performed with high accuracy and a minimum amount of scrap

Sheet metal cutting: description, types. metal bending

Today, sheet metal cutting is one of the fairly common technological processes that allows you to get blanks of the desired size and shape. However, there are many methods for performing this procedure and a wide variety of equipment

Cutting mode for milling. Types of cutters, calculation of cutting speed

One of the ways to finish materials is milling. It is used for processing metal and non-metal workpieces. The workflow is controlled by cutting data

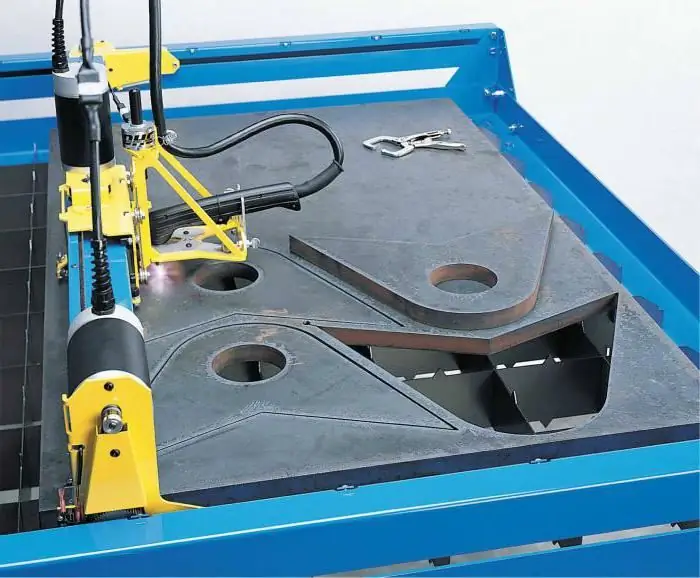

Metal cutting machine. Plasma metal cutting machine

The article is devoted to the apparatus for cutting metal. The technology of plasma cutting, as well as the device and features of the equipment are considered