2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

Push-button control stations are devices of a rectangular or square configuration in a case made of durable plastic, plastic or metal, inside of which push-button controls are mounted. Functionally and structurally, the devices may differ slightly from each other, but their principle of operation is identical - the transportation of alternating current through voltage circuits with indicators up to 600 volts (frequency - up to 60 Hz). As a result, the operating mode of the connected units changes. The controllers can also be operated with up to 400 V DC (settings can be changed in fixed or remote mode). The main scope of the devices under consideration is industrial sectors. The principle of operation of the device is the transfer of power to magnetic starters in the motor control circuit.

Purpose and functionality

Industrial push-button control stations are designed for remote control of various devices and devices with electric motors. Most often they are used in control circuits of three-phase motors of synchronous and asynchronous action.

Using pushbutton switches givesthe ability for the operator of the ventilation unit to adjust the operation of the unit from his workplace, without rising into the coverage area of the equipment. As a rule, push-button control posts are located on a common panel, the so-called common control post.

The main functions of the devices in question:

- Activation and deactivation of electrical appliances and apparatus.

- Carrying out a reverse (switching the direction of rotation of the rotor).

- Emergency shutdown of machines and other devices.

Operation in high-voltage circuits of the considered regulators is not provided.

Connection

Connection of push-button control stations and their subsequent operation is carried out using coils of magnetic starters, providing direct and reverse switching on of the motor. The control on the remote control is carried out by the buttons "Start", "Stop" ("Forward / Back").

When the Start-Forward pusher is activated, power is transmitted to the first magnetic starter through its coil, after which the group of contacts closes, providing power to the electric motor windings. When the "Start-back" function is activated, the second magnetic starter coil is blocked, while the normally open contacts close in parallel with the "Start-forward" mode.

Turning on the "Stop" key ensures that the electric motor is de-energized, while power is not supplied to both starters, the contacts are in an open state. When the reverse is activated, the operation of the contacts is similar to the start, only poweris fed to the second magnetic starter.

Features

Depending on the number of controlled consumers of electrical energy, push-button control stations can be two-button or multi-button. It should be noted that in the production of installation and electrical work, single buttons are used, which are installed by the user on any type of push-button switch.

The devices under consideration are installed in a metal or plastic case with mounting holes for fitting fittings at the place chosen as the main operational post. A separate category includes control panels for telphers (PKT), overhead hoists and overhead cranes with a ground type of control.

The main element of a push-button control station is a push-button, which is a switching electrical fitting with manual control. Consider the types of pushers and the devices themselves, their differences among themselves, as well as features by application.

Types of pushers

The pushers used in the design of the push-button control station, the price of which varies from 300 to 800 rubles (depending on the type and material of the body), are divided into two categories:

- Self-return options. Such buttons return to their original position by means of a spring located on the pusher at the bottom.

- Fixed (self-holding) models. Buttons of this type fix the contact tightly until pressed again.

Greatesta two-button modification has become widespread, the pushers are painted in a different color. In the free position, the Start button has open contacts, and the Stop button has closed contacts. Pushers may vary in color and shape:

- The color of the lock button is usually red or yellow.

- Pushers are available in black, blue, green or white.

- The shape of the buttons can be in the form of a mushroom, a cylinder, and also recessed into the body.

Types of remote controls

There is a wide range of push-button controllers on the market today. Functionally, they are almost identical, differing in brand, configuration and case material.

The PKE push-button control station is produced in Russia and is used to control industrial equipment. This series is mainly used in the schemes of metal-woodworking machines, as well as in the production of various mechanisms.

Instrument Performance:

- The switching voltage limit (AC/DC) is 600/400 volts.

- Switching current - 10 A.

- Trip cycles to the maximum - 5x10₆.

PKU push-button control posts are designed for use in an environment protected from explosions, where the accumulation of a gas-dust mixture will not provoke a violation of the integrity and operability of the controller. The parameters of this electrical fittings are similar to those of PKE.

PKT

This type of push-button control stations is designed for aggregation with electrical equipment of lifting devices such as electric hoists, overhead cranes and overhead cranes equipped with manual ground control. As a rule, this type of controller is used in various production workshops, warehouses, and special production facilities.

The characteristics of the operational and electrical plan are commensurate with those of the PKU and PKE versions. Also on the domestic market, Chinese-made electrical fittings are sold under the IEK marking. Its indicators are completely identical to Russian counterparts. The price also does not differ much from identical domestic modifications.

Explosion-proof push-button control station

Domestic explosion-proof controllers with pushers in the letter designation have an additional index "B", for example, PVC or KPVT. Such devices are used in the control circuits of equipment that is operated in an explosive environment (mines, oil storage facilities, paint shops and similar industries).

Posts like XAC-A (Germany) and KS (Poland) are widely used. Also in this segment, remote push-button electrical fittings are more often used.

Finally

PVK - push-button control station, which is used to control electrical equipment in an explosive environment. Analogues without index "B" are used in safer areas. The principle of operation of allregulators with pushers is identical, they differ in appearance and in the number of buttons. Models in a metal case are more durable and cost a little more. When choosing a post, one should take into account the features of its further operation and the compliance of the characteristics with the conditions of use.

Recommended:

How to pay a loan through the Post Bank application: step by step instructions, methods and reviews

For all smartphone owners there is a special modern application from Post Bank. You can download it for Android or iOS. All options of the official banking website can be used directly from the phone and quickly pay off loans while traveling by subway or bus

Control of cash operations of the bank. Overview of cash transactions control systems

Since various kinds of fraud often occur in the field of cash register accounting, every year the control of cash transactions becomes more and more complicated, tougher and modernized. This article discusses the role of the cash desk in the enterprise, the rules of conduct, as well as methods and systems for monitoring operations

Control object, control subject - complementary concepts

In management there are two concepts such as the object of management, the subject of management. Each organization is represented by an association of two subsystems. One of them is leading, and the other is controlled. But in both cases, they represent relationships between people

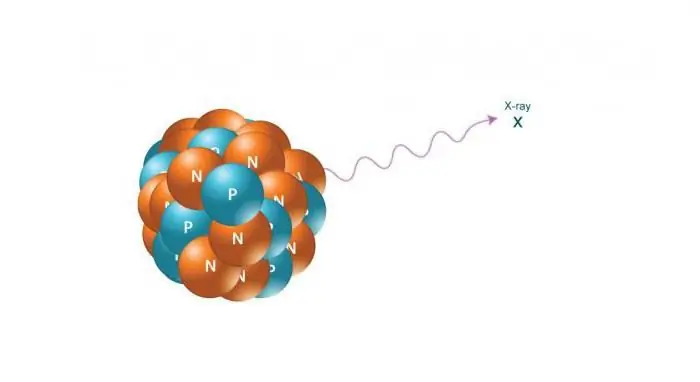

What is radiographic testing? Radiographic control of welds. Radiographic control: GOST

Physical bases of radiation control methods. Features of radiographic control. The main stages of radiographic control of welds. Safety precautions in the production of radiographic control. Normative and technical documentation

What does "Unsuccessful delivery attempt" mean ("Russian Post")? What is this operation? Statuses of FSUE Russian Post

Today, anyone can track their postal item, going "Russian Post". For this, there are special services that are able to unambiguously indicate where the package is now and what is happening to it