2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:32

Many years ago, lifting equipment was one of the main achievements of technology. But today, when advanced technologies and modern materials are being actively introduced, it is gradually becoming more traditional. Currently, there are a large number of companies that supply both various lifting equipment and a wide range of construction and industrial equipment.

Lifting equipment terminology

The term "lift" today is understood as a special technique that is able to function continuously or intermittently. Equipment such as cranes, elevators, etc., has the main purpose - the movement of various loads by a carrier moving along a high-strength vertical guide or along rail tracks. Lifting equipment today is represented by several varieties. The most common and most frequently used in almost all industrial areas are cargo lifts. In them, the device for moving the load is attached to a steel rope,envelope of the winch wound on a drum, or a traction sheave. Cranes operate mainly on electric drives, as well as on hydraulic ones.

Jib cranes

In the construction industry, console lifts are the most popular and in demand, which became possible due to the simplicity of their design and low cost. They are made in the form of mast racks without railings, relative to which platforms are placed in a cantilever way.

Safe operation of cranes largely depends on the correct type. It is worth noting that console-type equipment is divided into:

- Column crane. It is a stationary column along which cargo is lifted; it is widely used in machine-building production.

- Wall-console crane. It differs from the first option in that it consists of a wall truss, along which the cart moves. Installation method - stationary. The main advantage is the ability to work in small spaces. Typically, this type of crane is installed in order to reduce the load on overhead hoists.

Electric overhead mine crane

There are also mine cranes, which, unlike cantilever cranes, have a special device for protecting people, in which lifting cabins or platforms move along the guide. Basically, this technique is used in the mining industry. Overhead cranesDesigned for lowering / lifting large items. Thanks to a certain method of delivering goods, this type of equipment can significantly reduce costs, especially in comparison with an inclined shaft and a motor ramp. Compliance with safety rules when working with such cranes allows you to minimize the risk. The main advantage of this type of equipment is the fast and relatively safe transportation of heavy loads.

Portal cranes

This equipment moves along special paths, the number of which can vary from 1 to 3. The width of the knees is 6 m, 10.5 m, 15.3 m. The length of the boom can reach up to 100 meters. This type of crane is widely used in the shipbuilding industry, both in sea and river ports. Also, this equipment is used in floating docks and shipyards. Their specialization is quite narrow, they are used only for work in open areas.

Gantry cranes are divided into subspecies:

- mounting (KPM) - load capacity up to 300 tons;

- reloading (checkpoint) - designed for weights from 5 to 40 tons;

- dock (efficiency) - used to work with cargoes whose weight does not exceed 30 tons.

The design of the equipment is a portal with a swivel boom, which moves along the crane runways. Special hooks and grabs are used to lift loads.

Operation of load-liftingcranes

Before you start working on cranes, you must study the safety rules. All companies provide training. Some points may vary depending on the type of equipment, but the general essence of this documentation is the following points:

- working with electrical equipment;

- study and principle of operation of the main components of the crane (trolley, gallery, etc.);

- management method;

- braking ratio, etc.

Features of choice

There are a number of important factors to consider when choosing a material handling hoist for construction. This is the method of fastening, load capacity and many others. Additionally, various load-handling devices and devices are also used. In addition, you should take into account the frequency of lifting loads and calculate the approximate number of turns on and off the crane. Using the obtained data, it is possible to choose a lift taking into account the weight of the transported cargo. It is important to know the rules for the operation of cranes and their design features. This will secure and greatly facilitate the process of moving heavy objects.

Recommended:

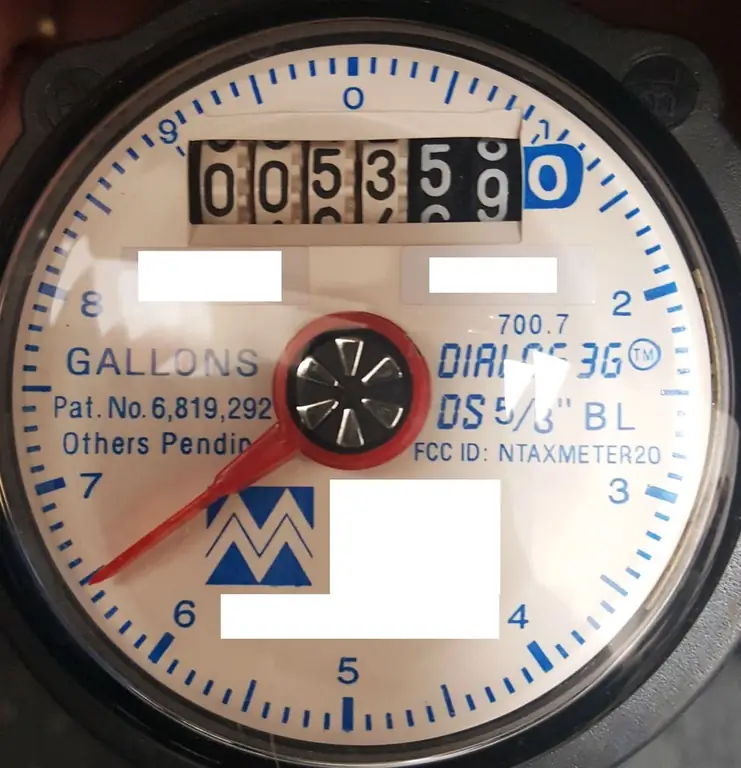

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

The best dust collector: overview, specifications and operating rules

Ventilation dust collector (UPV) is a device designed for air filtration. The separation of impurities is carried out in special filters

Diamond boring machine: types, device, operating principle and operating conditions

The combination of a complex cutting direction configuration and solid-state working equipment allows diamond boring equipment to perform extremely delicate and critical metalworking operations. Such units are trusted with the operations of creating shaped surfaces, hole correction, dressing of ends, etc. At the same time, the diamond boring machine is universal in terms of application possibilities in various fields. It is used not only in specialized industries, but also in private workshops

Duration of the operating cycle. What is an operating cycle?

The company will not have problems with a lack of current assets if the management begins to strictly control the proportions between equity and debt capital, through which operations are financed

Cable cranes: types and characteristics

Today, a variety of materials are used on construction sites. Many of them weigh quite a lot, and in order to successfully move them, you have to use special equipment. One such device is a cable faucet