2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Metal cutting is performed in order for the workpiece to acquire the desired shape. To this end, it is necessary to remove the excess. Such manipulation is carried out through the use of different cutting tools on special machines. In mechanical engineering, metal cutting is very important. Indeed, without this process, neither ordinary cars nor other devices can be made.

Application of technology

The cutting of metal by cutting is practiced in the initial roughing work and in the final operations, which are called fine processing. Indeed, such actions sometimes need to be performed, observing high accuracy: up to fractions of a micron. And this is a very small value.

Metal cutting is also practiced for large machine parts. For example, for hydraulic turbine rotors. The diameter of their impellers can exceed the mark of 9-10 meters. Also, those details that are difficult to see even under a microscope can be cut. Through processing, the element receives the desired shape, size, acquires the required surface quality. The service life of the product depends on this indicator.

Cutting theory

Such a science studies cutting metal in a similar way. It appeared at the end of the 19th century. Until now, they are engaged in it both in Russia and abroad. The key issue is the chip removal rate of the machine so that the tool life is maximized. It may seem to many that achieving high speeds is not so difficult. But it's not. The thing is that metal cutting develops heat. It heats and softens the tool for work, risking damaging it. It is very important to choose the right cooling for the cutter. But it doesn't always solve the problem. In addition, it can even damage the metal. Therefore, the speed of work depends partly on how the right machine was chosen. A tool for metal cutting should be purchased taking into account the properties of the material and its properties.

Features of the use of machines

Metal cutting machines are divided into types. They differ in the tool used. Also, the technology of metal cutting with their help is different. The most commonly used cutter. With it, you can perform operations of any complexity. All other tools are either a modification of it, or a combination of several types. There are two most common work patterns:

- turning, when the workpiece rotates, and the cutter slowly moves along its axis;

- planing - they both go forwardmovements.

The machines they need are completely different.

Features of metal cutting

As mentioned earlier, the process in question may occur atypically. And there are different ways of processing metals by cutting, for which the use of this or that equipment is provided.

In addition to turning and planing, milling and grinding are common work methods. However, the first method is the most popular. Mechanical processing of metals by cutting by various methods has a lot in common with sharpening. Therefore, if you learn this method, then there will definitely not be any problems with the rest in the future. And everything will be very simple in terms of work. Below are the features of using different types of machines.

Application of lathes

Cutting equipment varies. One of the key types of machine tools is a lathe. Its use has been practiced since ancient times. Then it was powered by rope devices like a bow for shooting. In such a field as metal cutting, turning is currently used to manufacture machine parts. Moreover, this is done so accurately and quickly that it will not be possible to achieve such goals mechanically.

The base of this type of machine is the bed. The workpiece must be clamped between the centers of the tailstock and headstock or in the chuck. Reinforce the cutter in the support. Set using a special box, reminiscent of an automobile, the required rotational speed for cutting. On the instrumentthere is a running roller, which comes into motion from it and displaces the caliper along with the cutter. If, in addition to it, there is a lead screw, then cutting can be performed using such a machine. When there is a swivel head instead of a tailstock, the tool is called a turret lathe. Such a cutting machine can perform various types of work. For the processing of products with a large diameter, tools such as a face-turning or rotary-turning apparatus are used. There are other types of it.

Improve the life of the lathe

Specialists are constantly working to find suitable materials that can increase the durability of working tools for metal cutting. Previously, machine tools were made on the basis of simple carbon steels, which had a simple composition in terms of chemistry. After that, materials with a high content of tungsten began to be used. With their help, it was possible to cut metals much faster. Therefore, they began to be called fast-cutting. However, over time, they also ceased to satisfy specialists in the field of mechanical engineering.

Then they were replaced when creating machine tools with hard alloys of a special class, which are able to maintain strength even at temperatures up to 100 degrees. In recent years, the process, which is based on metal cutting, has become even easier. This has been achieved through the use of materials with maximum resistance to high temperatures. Depending on the initial hardness of the workpiece, such as a cutter, as well as the type of work, it can be processed at the desired speed,which is regulated by means of a special box.

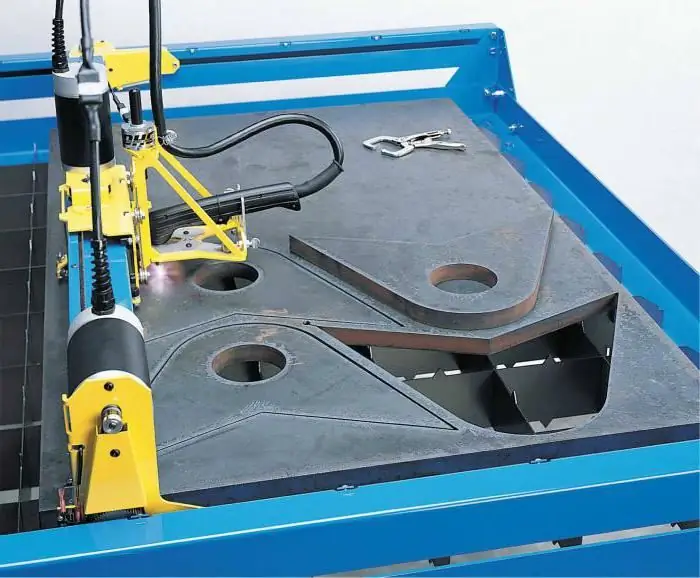

Milling as a type of metal processing

This method of work is quite widespread and is quite high-performance. It is carried out using a special milling machine. CNC (Computer Numerical Control) machines are being used more and more. Depending on the location of the caliper, they are divided into several types:

- vertical;

- horizontal;

- portal;

- longitudinal;

- gear milling;

- multi-spindle;

- single spindle and others.

Specialists in the manufacture of equipment of this kind are constantly improving it so that the productivity of metal processing is higher. The material of the machines is constantly changing, and its design is also changing. Like a cutter when planing, a milling cutter performs similar actions. But at the same time, it combines several of its types. And will be more productive. Due to this, milling is significantly superior to planing and is gradually replacing it in production.

Grinding features

Machines for this type of processing are used for grinding the inside and outside of round surfaces, different planes, centerless machining, threads, gears and more. Such a tool for metals belongs to the category of the most productive. In addition to a special machine, there is another device. This is a grinding wheel that includes a largethe number of small cutting elements. They, in turn, are fastened with a special binding device. And each particle in itself is a cutter. As you can see, we have covered metal processing equipment. Below we will get acquainted with more modern techniques that allow cutting it.

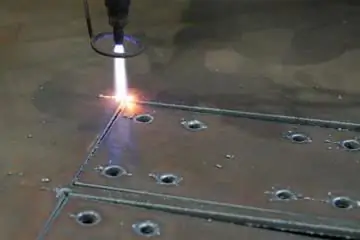

Features of plasma cutting technology

There are several techniques used for low carbon metals. But plasma cutting is considered one of the most productive. Therefore, it is worth dwelling on its features and advantages in more detail. The technology of the process is rapidly and constantly evolving. Plasma cutting of metals is widely used in various industrial areas: from the construction of houses to mechanical engineering. Along with the oxygen-gas method, it is considered quite promising.

Key Benefits

The method of plasma cutting of metals has a large number of advantages. One of them is the speed of work. Most often, blanks for cutting have a thickness of up to 25 mm. In this case, the speed of their processing is approximately twice and even more than that when using oxy-gas cutting. And it is worth adding that with a noticeable decrease in the thickness of the metal sheet, it can exceed it by 12 times. This advantage can significantly increase productivity and save time.

Another advantage of the method is the high and high-quality burn speed. This characteristic is very important when cuttingmetal products. With the plasma method, it is about 2 seconds. For comparison: gas cutting with oxygen - 30, respectively, subject to a temperature of 1 thousand degrees at least. The short interaction of the tool with the metal is good, first of all, because in a couple of seconds the material will not have time to deform, as it can happen in another case.

Another undoubted advantage of the plasma method is the minimum amount of scale during operation. It can be easily removed. The cutting systems are also easy to operate and help to provide the right tool height and good speed.

Saving time and money

Plasma cutting also involves cutting multiple sheets at the same time, which saves a lot of time. With this method, different types of materials can be processed:

- aluminum;

- stainless steel;

- copper and more.

It is impossible not to note the safety of the use of plasma systems. They do not use combustible gases, open fire, and do not release much heat. All this significantly reduces the possible risks for users when working with hot metals. The heat affected area is only 2 millimeters.

All characteristics of plasma cutting have a positive effect on the cost of recycling materials. Works are carried out qualitatively, quickly and universally. For many purposes, these advantages are more preferable than others.

Features of lasermethod

Today, many technologies have been introduced in the field of processing metal products. They can greatly facilitate the work of designers, builders and other professionals whose work is somehow related to this process. Laser cutting is currently considered the most advanced. It allows you to get great opportunities in the manufacture of metal products in terms of design and various configurations.

Such a promising technique is quite young, but already widely distributed. Laser cutting of metal is carried out by means of focused technically powerful special installations. They are characterized by high beam concentration. And they are able to cut not only aluminum or copper, but also wood and other materials.

Method Description

With this method of cutting, oxides appear on the surface of the metal. They increase the energy absorption process and are able to maintain the temperature up to the melting point. At the contact point, the laser beam creates maximum temperature values, as a result of which the material begins to melt. But outside the specified zone, it only heats up. Along with this, an active gas is supplied, most often it is oxygen. It blows out the products of combustion and allows you to significantly increase the cutting speed. Oxygen heats multiple layers by removing liquid metal and oxides.

All this happens while the material is not cut through to its full depth. After all, a jet of gas near the separation lines is able to actively cool it. A small heat-affected zone canensure the creation of parallel edges at small distances from each other (about 0.2 mm). Very often, in order to achieve one or another accuracy during the cutting operation, it becomes necessary to introduce automated control by means of a computer. In such cases, you can program the creation of a finished product.

For laser cutting of sheet metals, equipment based on solid-state and gas tools is most often used. In this case, the cut of the material is perfectly even. No mechanical metal cutting can provide such accuracy, taking into account prompt execution and with a minimum amount of waste. In general, for sheet metal processing, devices based on gas and solid-state lasers are used. The laser cut of the metal will be perfectly even. It will turn out without deformations that are present during a mechanical cut. In addition, laser cutting technology allows for significant work precision, minimal waste and fast turnaround times.

Method advantages

Laser cutting is one of the most demanded in the metal products cutting market. It has made working with carbide materials much easier. After all, they are quite complex in terms of processing and could often worsen after such manipulations. Best for laser cutting:

- steel;

- non-ferrous metals;

- aluminum alloys.

Thick sheets toomuch better processed. It will be easier to work with complex shapes of metal parts and make holes in very hard materials with a small diameter. Here, in terms of geometry, you can give free rein to your imagination. The system can be automated. To do this, it is enough to create a special file with a given program on a computer. There will be no mechanical effects on the metal - this is also important. The following advantages have also been observed with laser processing:

- Ability to create a complex cut contour.

- Almost any sheet metal can be machined regardless of its thermal properties.

- High precision work.

- Cutting is possible even on easily deformable and not too hard materials.

- High productivity due to high laser power.

- If the surface needs to be smooth, it is better to use a focused beam with adjustable power.

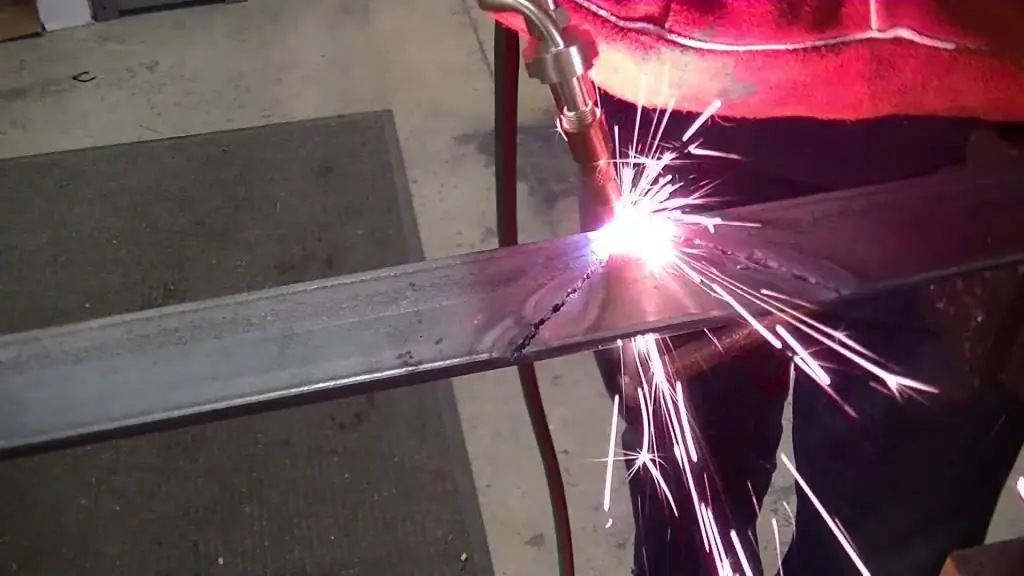

Gas method

Let's consider a fairly common method of influencing metal, which has been actively used for many years. This is gas cutting. It is quite popular and cost effective. In another way, it is also called oxygen, since in this case the process of influencing the metal is of a thermal nature. There is a stream of oxygen after the end of work and removes the remains of liquid oxide. To begin with, the upper edge of the part is heated. Depending on the chemical composition of the material (for example, steel), its ignition temperature can range from 1000 to 1200 degrees.

Gas cutting canbe applied to medium alloy, low alloy or carbon steel. The thickness of the metal sheet or other product must be a maximum of 300 millimeters. The gas-oxygen method of metal processing has its advantages:

- Low processing costs.

- There is no need to work with the edge after the procedure is completed.

- Availability of straight and diagonal cutting of products at different angles.

- Thick metal sheets can be used.

Is there a work standard?

Many are wondering if metal cutting has GOST or other standards regarding the execution of structural processing. So, according to the existing rules and criteria, such a process has its own tasks. First of all, the details must be given one or another configuration and dimensions. This is required by the technological documentation used. For example, an approved project for the construction of an object. Also, the surface to be treated must always be clean according to accepted standards. GOSTs list mechanical methods of metal cutting, including turning, drilling, milling, as well as slotting, broaching. The final processing of products is also indicated. Each type of mechanical processing of metals corresponds not only to certain equipment, but also to a serial number.

As we have seen, there are many ways of mechanical and automated processing of products in order to cut them. All this is widely used in construction, engineering,repair and other areas. Methods are constantly being improved and supplemented with new ones, modern equipment is being created, which each time makes the process more and more simple.

Recommended:

Oxyfuel cutting of metal: technology, necessary equipment, safety precautions

Oxy-fuel cutting of metals (in the literature you can find the term "oxy-fuel cutting") is actively used in industry for cutting sheet material from steel and other alloys into workpieces of the required length. The article contains information about the technology itself, about the necessary equipment and basic safety precautions for oxygen cutting of metals and other materials

Project implementation methods. Methods and tools for project implementation

The term "project" has a specific practical meaning. Under it is understood something once conceived. The project is a task with some initial data and goals (required outcomes)

Types of metal cutting: an overview of modern technologies and equipment

One of the most common metalworking operations is cutting. It is a technological process during which a sheet or billet is divided into parts of the desired format. Modern types of metal cutting allow this operation to be performed with high accuracy and a minimum amount of scrap

Metal cutting machine. Plasma metal cutting machine

The article is devoted to the apparatus for cutting metal. The technology of plasma cutting, as well as the device and features of the equipment are considered

Metal cutting with plasma. Metalworking equipment

When buying a plasma cutter, you should always prioritize quality. Beware of the temptation to buy a cheap low-quality device, as its rapid wear and tear in the long run will lead to much higher costs