2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

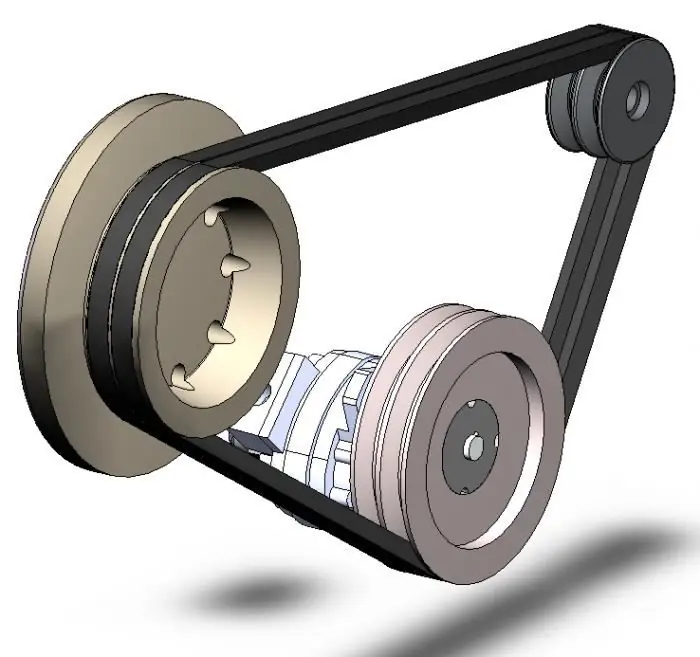

V-belt is the main connecting device used in the manufacture of various types of machine tools, mechanisms and machines with moving components. This tool transmits the inertial rotational movements of the engine (or any other mechanism) and brings them into final contact. At the same time, V-belts bypass the corresponding pulleys during operation and transfer of forces from one mechanism to another.

It is worth noting that the section of this tool forms a kind of isosceles trapezium. Moreover, its shape may differ significantly from the standard according to which this belt model is produced.

Features

Each model of the V-belt is made using a special technology, taking into account the addition of several layers of rubber, fastened together with a high-quality adhesive. The main layers of this tool are:

- Wrap cover.

- Compression and stretch layer.

- Traction layer.

Each of the above layers allows the product not to lose its elasticity properties under the enormous loads that affect it during engine rotation and transmission of traction. Thus, the presence of several layers and coatings in the composition of this device gives a guarantee for the longest possible period of its operation. V-belts can withstand enormous loads for a very long time and not tear to the point of wear. However, if at least one tear has formed on its surface, this means that such a tool is no longer suitable for further use. It is simply impossible to repair or restore the properties of such a belt, and the presence of cracks and other deformations will certainly lead to a break in the mechanism. When this happens, it is a matter of time, but the fact that the damaged layer of the device will constantly aggravate the performance of the entire mechanism remains unchanged.

Rubber Quality

Only the most heat-resistant and oil-resistant grades of rubber can be included in the composition of such a part as a V-belt. These requirements are determined by the operating conditions of this mechanism, since its operation is always accompanied by constant heating and friction. In addition, the V-belt must have high wear resistance qualities. In some cases, the temperature of this device during continuous operation can reach more than 100 degrees Celsius. Considering that such a V-belt is inconstantly suspended and transfers forces from one mechanism to another, low-quality parts will fail immediately after the first hours of operation. Real belts (for example, those used for timing cars) can work up to 80-90 thousand kilometers without a single tear or deformation.

Textile fiber

To achieve maximum strength and wear resistance, these tools include a special textile fiber. On broken belts, it can be seen on the very first layers - these are thin threads intertwined with each other, which are very difficult to break even with a knife.

Recommended:

Glass furnace: types, device, specifications and practical application

Today, people actively use glass for a variety of purposes. The glassmaking process itself is the melting of raw materials or charge. Glass melting furnaces are used to melt the material. They come in different types and are classified according to several criteria

Mobile gas station: description, device, principle of operation, application

Mobile gas station is quite a popular business idea these days. Therefore, the achievement of any success in this area can only be possible if you pay maximum attention to the various key points that are described in this article

Aircraft device for dummies. Aircraft device diagram

Few people know how an airplane works. Most don't care at all. The main thing is that it flies, and the principle of the device is of little interest. But there are people who cannot understand how such a huge iron machine rises into the air and rushes at great speed. Let's try to figure it out

Magnetic flaw detectors: device and application. Unbrakable control

The article is devoted to magnetic flaw detectors. The device of devices, varieties, as well as the technology of application are considered

Main busbar: description, types and device, application

Power supply wiring in manufacturing plants and construction sites needs additional protection. Conventional insulation does not always cope with these tasks, so special circuits are used that also perform the functions of distribution and optimized connection. A typical version of such wiring is a trunk bus duct containing one or more power lines