2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:41

Acetylene generator is a device for producing acetylene by a chemical reaction. The interaction of calcium carbide with water leads to the release of the desired product. Currently, such devices are used both in stationary and mobile gas installations. Actually, acetylene is the main fuel in gas welding. Let's talk in more detail about what this equipment is and what its key features are.

Classification of generators

Acetylene generators are usually classified according to several criteria, including performance, method of application, pressure and principle of operation. As for pressure, there are acetylene generators with low pressure - up to 0.01 MPa, medium - 0.07-0.15 MPa, high - more than 0.15 MPa.

According to the method of movement, the acetylene generator can be stationary and mobile. The latest devices are less productive - 0.3-3 m3, stationary ones produce from 5 to 160 m3 of combustible gas per hour. As regards the principleactions, then the following types should be noted: KV - mixing carbide and water, VK - water on CaC2 with a possible "wet process". In addition, welders often use VC, but only with a “dry process”. It is extremely rare, but combined generators are still used. They combine the features and specifications of different types that complement each other.

The principle of operation of the acetylene generator

As noted a little above, the design and how the unit works is determined by its type. First, let's look at the carbide-to-water generator. It is the most popular and simple.

The principle of action is as follows. Carbide through the bunker in a certain portion is fed into the gas-forming chamber. At this time, it passes through the feeder. The gas chamber contains water. As for the supply of carbide, it is regulated automatically and largely depends on the pressure in the system. After filing the next portion, the pressure in the gas-forming chamber increases. If it falls below a critical level, the next portion is loaded.

Directly during the interaction, the formation of that very acetylene occurs. It enters a special hose through a sampler. Slaked lime is removed through a special bunker.

How the water-to-carbide generator works

In this case we will talk about the so-called "wet process". The principle of operation of such a generatorsimilar to the one described above with the only difference. Here, water is periodically supplied to the carbide, from where, in fact, the name came from. A clear advantage of this solution is that, with the maximum simplicity of the design, the reliability of the unit is quite high. Of course, there are also disadvantages here, which are expressed in the incomplete decomposition of calcium carbide, as well as the possible overheating of acetylene due to the insufficient size of the boot device. Such units are very rarely stationary, due to their low productivity, which does not exceed 10 m3/hour. For example, the ASP-10 acetylene generator works exactly according to this principle. It has a light weight - 16.5 kg, as well as a productivity of 1.5 m3/hour.

"Water on carbide" according to the principle of "dry process"

The essence of the operation of such generators is that in the gaseous chamber there is a drive drum with carbide. There is also a semi-automatic carbide feeding system. It is loaded into the drum through special hatches. Water is also added to this. In this case, it is extremely important to observe the correct dosage of the liquid. Its amount should be exactly twice as much as is necessary for the decomposition of the carbide. Since a lot of heat is released during a chemical reaction, the excess water evaporates and does not need to be removed. As for the slaked lime, it falls out through the bottom grate of the drum and is then removed.

In this case, the acetylene generator device allows you to get dry lime due to the fullevaporation of liquid in the system. Hence, in fact, the name "dry process" appeared. As for the advantages of such a solution, they are simple maintenance and removal of spent carbide. Usually these are stationary type generators with average performance.

Water displacement system

The design difference of such acetylene generators lies in the features of the gas-forming chamber. It consists of two interconnected vessels (displacer and gas generator). Carbide is loaded into the latter, which is why water is displaced into the air cushions of the displacer. Through the sampler, acetylene is removed from the chamber.

The amount of loaded carbide, as well as the performance of the device, are automatically adjusted. True, the process depends on pressure. The higher it is, the slower it flows, and vice versa. Interestingly, the operation of an acetylene generator of this type can be smoothly regulated, which is a strong point of the device. Also, the "water displacement" system is famous for its reliability. The main disadvantage is that the maintenance of productive plants is very difficult. That is why acetylene generators of this type are made mobile and have low productivity.

Combined Generators

Welding equipment often combines "water to carbide" and "water displacement" systems. The principle of operation is that in the gas collection chamber there is a basket with carbide into which water is supplied. In a chemical reactionacetylene is formed. If there is excess pressure in the system, then water is forced out into the air bag of the displacement chamber. Acetylene is removed through a check valve, after which it leaves the chamber.

In the event of a pressure drop, the water from the displacer flows back into the basket and thereby stimulates the formation of acetylene. For the most part, such systems are made mobile. Combined acetylene generators have a high smoothness of operation and the absence of such a negative factor as pressure drop in the system. Devices have low performance, but are in great demand.

Low pressure acetylene generator device

The case of such a device has two separate chambers. The upper one is a water collector, the lower one is a gas collector. Between themselves, they are separated by a special partition. The gas collection chamber has a retort, which is located at the bottom. A basket with carbide is placed in it. After loading, it is hermetically sealed, for which rubber gaskets are used as a seal.

Water is supplied from above with a tap. When it enters the retort, the carbide process starts, which then goes into the gas collection chamber. Then it enters the dryer and water lock, after which it goes to the cutter or gas burner.

Pressure adjustment is automatic. As it increases, liquid is displaced from the retort. When the water drops below the level of the faucet, the formation of acetylene is significantlyslows down. Such welding equipment is capable of operating at an ambient temperature of -25 degrees Celsius, which, without a doubt, is an advantage.

Medium and high pressure generators

Acetylene generator ASP-10 refers to equipment operating in the medium pressure range. The device is identical in principle to low pressure generators. But here - large dimensions and corresponding performance. Of the design features, it is worth noting the presence of a box through which water passes. In addition, elementary water cooling of acetylene is provided here. This is due to the high operating pressure and high gas temperature.

Conclusion

So we figured out what an acetylene generator is. The price of such equipment directly depends on its type. So, ASP-10 will cost about 20,000 rubles. The more productive the unit, the more expensive it is. Full-fledged stationary high-pressure installations cost from 30,000 rubles and more. When choosing, it is necessary to take into account at what temperatures the equipment operates. The wider the range, the more versatile it is. In general, this is all the basic information on this topic. Now you know what an acetylene generator is, what types of these devices are, what are their design and technical differences.

Recommended:

Classification of engines. Types of engines, their purpose, device and principle of operation

Nowadays, most vehicles are powered by an engine. The classification of this device is huge and includes a large number of different types of engines

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Use of acetylene. Acetylene welding

To understand where acetylene is used, it is necessary to study and understand what it is. This substance is a flammable colorless gas. Its chemical formula is C2H2. The gas has an atomic mass of 26.04. It is slightly lighter than air and has a pungent odor

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities

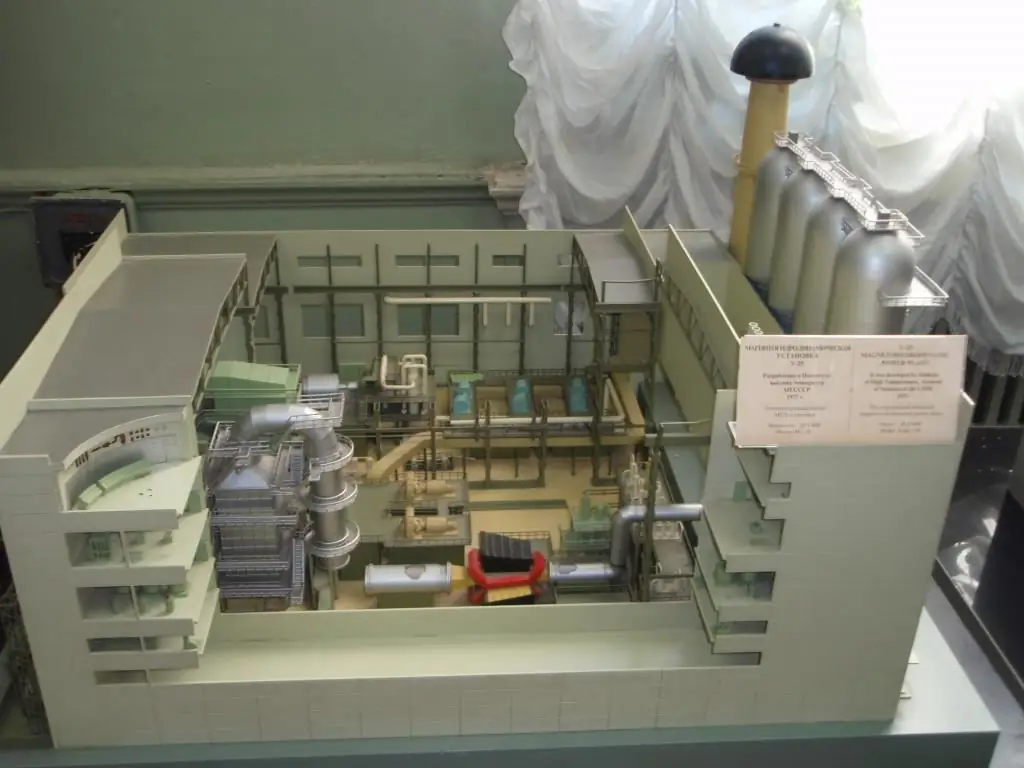

Magnetohydrodynamic generator: device, principle of operation and purpose

Not all alternative energy sources on planet Earth have been studied and successfully applied so far. Nevertheless, humanity is actively developing in this direction and finding new options. One of them was obtaining energy from an electrolyte, which is in a magnetic field. Typical operation cycle and main classifications of MHD generators. List of main characteristics. Perspective and applications