2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:43

Not all alternative energy sources on planet Earth have been studied and successfully applied so far. Nevertheless, humanity is actively developing in this direction and finding new options. One of them was getting energy from the electrolyte, which is in a magnetic field.

Designed effect and origin of the name

The first works in this field are attributed to Faraday, who worked in laboratory conditions as early as 1832. He investigated the so-called magnetohydrodynamic effect, or rather, he was looking for an electromagnetic driving force and tried to successfully apply it. The current of the River Thames was used as a source of energy. Along with the name of the effect, the installation also received its name - a magnetohydrodynamic generator.

This MHD device directly converts oneform of energy into another, namely mechanical into electrical. The features of such a process and the description of the principle of its operation as a whole are described in detail in magnetohydrodynamics. The generator itself was named after this discipline.

Description of effect action

First of all, you should understand what happens during the operation of the device. This is the only way to understand the principle of the magnetohydrodynamic generator in action. The effect is based on the appearance of an electric field and, of course, an electric current in the electrolyte. The latter is represented by various media, for example, liquid metal, plasma (gas) or water. From this we can conclude that the principle of operation is based on electromagnetic induction, which uses a magnetic field to generate electricity.

It turns out that the conductor must intersect with the field lines of force. This, in turn, is an obligatory condition for the flows of ions with opposite charges relative to the moving particles to begin to appear inside the device. It is also important to note the behavior of the field lines. The magnetic field built from them moves inside the conductor itself in the opposite direction from the one where the ion charges are.

Definition and history of the MHD generator

The installation is a device for converting thermal energy into electrical energy. It fully applies the aboveEffect. At the same time, magnetohydrodynamic generators were considered at one time to be quite an innovative and breakthrough idea, the construction of the first samples of which occupied the minds of leading scientists of the twentieth century. Soon, funding for such projects ran out for reasons that are not entirely clear. The first experimental installations have already been erected, but their use has been abandoned.

The very first designs of magnetodynamic generators were described back in 1907-910, however, they could not be created due to a number of contradictory physical and architectural features. As an example, we can cite the fact that materials have not yet been created that could function normally at operating temperatures of 2500-3000 degrees Celsius in a gaseous environment. The Russian model was supposed to appear in a specially built MGDES in the city of Novomichurinsk, which is located in the Ryazan region in close proximity to the state district power plant. The project was canceled in the early 1990s.

How the device works

The design and principle of operation of magnetohydrodynamic generators for the most part repeat those of ordinary machine variants. The basis is the effect of electromagnetic induction, which means that a current appears in the conductor. This is due to the fact that the latter crosses the magnetic field lines inside the device. However, there is one difference between machine and MHD generators. It lies in the fact that for magnetohydrodynamic variants asconductor is used directly by the working body itself.

The action is also based on charged particles, which are affected by the Lorentz force. The movement of the working fluid occurs across the magnetic field. Due to this, there are flows of charge carriers with exactly opposite directions. At the stage of formation, MHD generators used mainly electrically conductive liquids or electrolytes. It was they who were the very working body. Modern variations have switched to plasma. The charge carriers for the new machines are positive ions and free electrons.

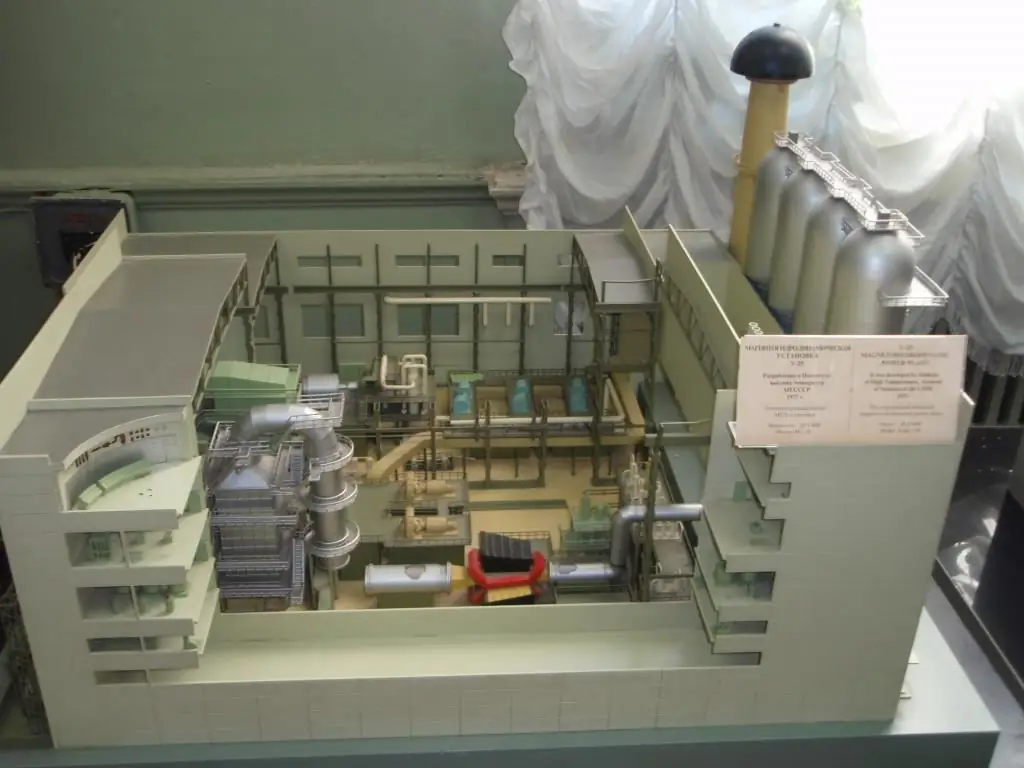

Design of MHD generators

The first node of the device is called the channel through which the working fluid moves. At present, magnetohydrodynamic generators mainly use plasma as the main medium. The next node is a system of magnets that are responsible for creating a magnetic field and electrodes to divert the energy that will be received during the work process. However, the sources may be different. Both electromagnets and permanent magnets can be used in the system.

Next, the gas conducts electricity and heats up to the thermal ionization temperature, which is approximately 10,000 Kelvin. After this indicator must be reduced. The temperature bar drops to 2, 2-2, 7 thousand Kelvin due to the fact that special additives with alkali metals are added to the working environment. Otherwise, the plasma is not sufficientdegree effective, because the value of its electrical conductivity becomes much lower than that of the same water.

Typical device cycle

Other nodes that make up the design of the magnetohydrodynamic generator are best listed along with a description of the functional processes in the sequence in which they occur.

- The combustion chamber receives the fuel loaded into it. Oxidizing agents and various additives are also added.

- The fuel starts to burn, allowing gas to form as a product of combustion.

- Next, the generator nozzle is activated. Gases pass through it, after which they expand, and their speed increases to the speed of sound.

- The action comes to a chamber that passes a magnetic field through itself. On its walls are special electrodes. This is where the gases come in at this stage of the cycle.

- Then the working body under the influence of charged particles deviates from its primary trajectory. The new direction is exactly where the electrodes are.

- The final stage. An electric current is generated between the electrodes. This is where the cycle ends.

Main classifications

There are many options for the finished device, but the principle of operation will be virtually the same in any of them. For example, it is possible to launch a magnetohydrodynamic generator on solid fuel like fossil combustion products. Also as a sourceenergy, alkali metal vapors and their two-phase mixtures with liquid metals are used. According to the duration of operation, MHD generators are divided into long-term and short-term, and the latter - into pulsed and explosive. Heat sources include nuclear reactors, heat exchangers, and jet engines.

In addition, there is also a classification according to the type of work cycle. Here the division occurs only into two main types. Open cycle generators have a working fluid mixed with additives. The combustion products go through the working chamber, where they are cleaned of impurities in the process and released into the atmosphere. In a closed cycle, the working fluid enters the heat exchanger and only then enters the generator chamber. Next, the combustion products are waiting for the compressor, which completes the cycle. After that, the working fluid returns to the first stage in the heat exchanger.

Main Features

If the question of what produces a magnetohydrodynamic generator can be considered fully covered, then the main technical parameters of such devices should be presented. The first of these in importance is probably power. It is proportional to the conductivity of the working fluid, as well as the squares of the magnetic field strength and its speed. If the working fluid is a plasma with a temperature of about 2-3 thousand Kelvin, then the conductivity is proportional to it in 11-13 degrees and inversely proportional to the square root of the pressure.

You should also provide data on the flow rate andmagnetic field induction. The first of these characteristics varies quite widely, ranging from subsonic speeds to hypersonic speeds up to 1900 meters per second. As for the induction of the magnetic field, it depends on the design of the magnets. If they are made of steel, then the upper bar will be set at around 2 T. For a system that consists of superconducting magnets, this value rises to 6-8 T.

Application of MHD generators

Wide use of such devices today is not observed. Nevertheless, it is theoretically possible to build power plants with magnetohydrodynamic generators. There are three valid variations in total:

- Fusion power plants. They use a neutronless cycle with an MHD generator. It is customary to use plasma at high temperatures as fuel.

- Thermal power plants. An open type of cycle is used, and the installations themselves are quite simple in terms of design features. It is this option that still has prospects for development.

- Nuclear power plants. The working fluid in this case is an inert gas. It is heated in a nuclear reactor in a closed cycle. It also has prospects for development. However, the possibility of application depends on the emergence of nuclear reactors with a working fluid temperature above 2 thousand Kelvin.

Device Perspective

The relevance of magnetohydrodynamic generators depends on a number of factors andproblems still unresolved. An example is the ability of such devices to generate only direct current, which means that for their maintenance it is necessary to design sufficiently powerful and, moreover, economical inverters.

Another visible problem is the lack of necessary materials that could work for a sufficiently long time in conditions of fuel heating to extreme temperatures. The same applies to the electrodes used in such generators.

Other uses

In addition to functioning at the heart of power plants, these devices are able to work in special power plants, which would be very useful for nuclear energy. The use of a magnetohydrodynamic generator is also allowed in hypersonic aircraft systems, but so far no progress has been observed in this area.

Recommended:

Classification of engines. Types of engines, their purpose, device and principle of operation

Nowadays, most vehicles are powered by an engine. The classification of this device is huge and includes a large number of different types of engines

Driver controller: purpose, device and principle of operation

The use of a variety of vehicles today is very active. They all have in common that they need to be managed. The driver's controller is also designed for control. With it, you can remotely control the traction motor in braking or traction mode

Reservoir breathing valve: purpose, device, principle of operation, verification

Oil refineries and technological complexes using oil and gas products contain a system of pipelines for servicing fuel materials in their working infrastructure. Maintaining sufficient performance in the circulation circuits of the same oil requires the use of special plumbing fittings. Its key element is the reservoir breather valve, through which the pressure is regulated

General purpose engines: device, principle of operation, application, photo

Automotive equipment is mainly equipped with standardized internal combustion engines (ICEs), the design of which is focused on placement in the engine compartment. However, there is a great demand for power units of this kind in the garden equipment segments, from manufacturers of snowplows, snowmobiles, etc. Moreover, the requirements for integration and operational parameters in such cases differ sharply from automotive standards

Acetylene generator: device and principle of operation

Acetylene generator is a device for producing acetylene by a chemical reaction. The interaction of calcium carbide with water leads to the release of the desired product. Currently, such devices are used both in stationary and mobile gas installations