2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:27

The segment of kitchen appliances belongs to the areas that contribute to the development of technological progress. Microwave ovens, refrigeration units, electric and gas stoves are often the first to be endowed with innovative technologies, which are then extended to other appliances. In this sense, an industrial meat grinder is one of the most demanding units, since it must not only provide a basic set of culinary operations, but also maintain optimal power indicators. Catering enterprises, sausage production lines and other areas of the food industry are actively using the capabilities of productive meat grinders, at the same time improving product quality and production rates.

Equipment for the food industry

The technological equipment of enterprises whose activities relate to the production of food products is very extensive and diverse. These include food preparation facilities, cooking equipment, and service systems. In particular, equipment for the food industry includes breading machines, meat presses, mixers, dumplings, tenderizers, meat mixers, dough mixers,bread slicers and many universal devices. And this is not counting devices that provide packaging of finished products, cleaning kitchen tools, primary preparation of products, etc.

Against this background, the meat grinder is not perceived as such an important element of production workshops, however, without it, it is impossible to implement most culinary chains in which the use of meat products is expected. In addition, the industrial electric meat grinder is not at all limited to processing meat to form minced meat - its device also makes it possible to grind fish, vegetables and fruits.

Device Features

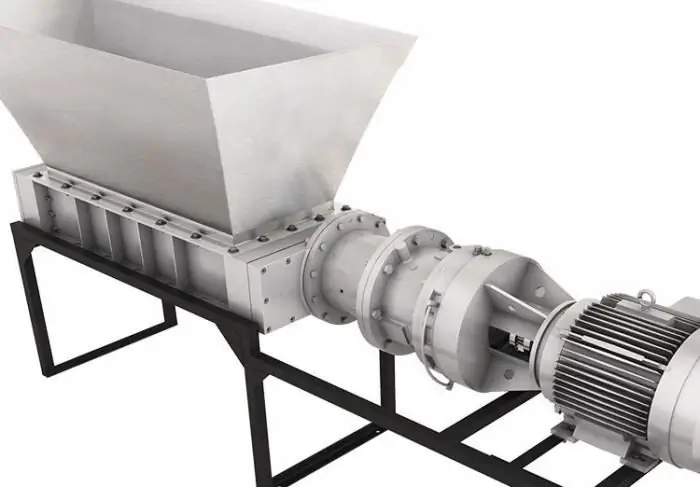

Today, mechanical units are still in some demand, but the trend of reduction in this segment is obvious. And, on the contrary, electric models, the design of which seems to be more relevant, are in stable demand. Let's start with the distinguishing features. So, in comparison with the mechanical counterpart, the industrial electric meat grinder has a metal or plastic neck without extensions in the upper part. It also mounts a tray for processed meat.

The main feature is the electric drive, which in some modifications is supplemented with a fan for cooling. The rest of the unit is quite simple: an aluminum or steel housing contains an auger, special knives and a clamping screw. In addition, the presence of knife gratings and a cutting element is possible.

Safety systemssecurity

In electric meat grinders for industrial use, different systems of protection against engine overheating can be provided. Models available on the Russian market are equipped with two mechanisms that protect the machine in case of problematic meat processing. For example, if a bone is stuck or wound tendons make it difficult for the screw mechanisms to move. In the first case, meat grinders are equipped with plastic gears on the screw itself and the gearbox, which break on purpose, freeing up the course. As a result, the motor does not overheat, and as a rule, there is a second set to replace the gears.

Another principle, on the basis of which the industrial meat grinder is protected from the failure of the electric motor, provides for the presence of a disconnecting clutch. Its function also comes down to stopping the relationship between the engine and the working parts - the clutch simply opens the auger and the electric drive, which then runs idle.

Packages

There are three configurations of meat grinders designed for professional use. The standard equipment of the machine includes a one-sided knife, an auger and grates. This is the simplest set of mechanisms, optimal for small canteens and cafes.

The next most difficult equipment is called "half-unger". This specification includes auger and reversible knives for industrial mincers that can be installed after the scoring component. A feature of such models is the ability to separate meatbefore grinding directly.

The “Unger” package is distinguished by the presence of two gratings (large and small), an auger and a double-sided knife. In terms of workmanship, this option is similar to the second configuration, but its design with two gratings expands the operational capabilities.

Power and performance

Correct correlation of requirements for production volumes with the capabilities of the unit will allow you to get rid of possible problems in operation. In general, equipment for the food industry is initially focused on the processing of large volumes of products. However, there is a difference in the scale of supplies to catering establishments and the supply of a small canteen and shop - for this reason, you should decide on the capacity of the meat grinder.

There are four categories of aggregates in terms of performance. These are meat grinders capable of producing up to 50, 150, 300 and 600 kg of minced meat per hour. In terms of power potential, an industrial meat grinder is capable of demonstrating performance of 1.5-3 kW. This is quite enough to service sausage shops operating around the clock.

Faults and repairs

The complexity of meat processing equipment leads to quite clear operating rules. However, there are problems that cannot be insured against. Usually, industrial meat grinders are repaired when regular cleaning does not help. Among the main causes of malfunctions are kinks in the joints, gear breakage, failedelectric motor and problems with cutting meat into minced meat.

Depending on the safety system, a gear failure in the auger or gearbox, as already noted, may be associated with a delay in meat processing - in this case, you can replace the elements from the spare set. The same applies to other repair operations - spare parts for industrial meat grinders should always be prepared, including drive shafts, blocks, screw elements, knives, grate nozzles and other elements. The presence of such a kit will allow you to cope with the repair of the motor, replace or repair a dull knife, restore connections, etc.

Nozzles for meat grinders

Manufacturers of industrial meat grinders seek to expand their functionality not only by increasing the design capabilities, but also through various attachments. In particular, sets of modern units contain special baths - this is an addition that allows you to fill sausages or sausages with minced meat.

There are other devices with the help of which the industrial meat grinder acquires new functional properties. Nozzles can also be distinguished by the type of product being manufactured. Some devices allow you to pass meat, fish or vegetables through a grater, others divide the minced meat according to the noodle principle into uniform portions by means of modeling, and still others even work as a juicer.

Conclusion

Assessing the advantages and capabilities of professional meat grinders, for suremany will want to have such a unit at home, although the decision to purchase such models is more advisable for commercial and public enterprises. This is also evidenced by the fact that the meat grinder is industrial, the price of which varies from 25 to 40 thousand rubles. on average, quite profitable in regular production cycles. It pays for itself in a short time, and if you use the full potential of the unit, entrusting it with related culinary operations, you can do without other industrial equipment in production. For example, the functions of cutting, cooking noodles, sausages and dumplings also allow you to perform some models of professional meat grinders. Again, the main thing is to match the requirements of production and the functionality of the equipment.

Recommended:

Food stainless steel: GOST. How to identify food grade stainless steel? What is the difference between food stainless steel and technical stainless steel?

The article talks about grades of food grade stainless steel. Read how to distinguish food stainless steel from technical

Street fast food equipment: the advantage of fast food outlets

Have you decided to go into business and don't know where to start? You may be interested in making a profit from such a dynamically developing type of business as fast food. Investments are minimal: equipment for street fast food is inexpensive. You just need to decide what to produce, and locate the mobile point in the vicinity of potential buyers

Clothing industry as a branch of light industry. Technologies, equipment and raw materials for the clothing industry

The article is devoted to the clothing industry. The technologies used in this industry, equipment, raw materials, etc. are considered

Dairy industry in Russia. Dairy industry enterprises: development and problems. Dairy and meat industry

In the economy of any state, the role of the food industry is huge. Currently, there are about 25 thousand enterprises in this industry in our country. The share of the food industry in the volume of Russian production is more than 10%. The dairy industry is one of its branches

Meat: processing. Equipment for meat and poultry processing. Production, storage and processing of meat

Information of state statistics show that the volume of meat, milk and poultry consumed by the population has significantly decreased in recent years. This is caused not only by the pricing policy of manufacturers, but also by the banal shortage of these products, the required volumes of which simply do not have time to produce. But meat, the processing of which is an extremely profitable business, is very important for human he alth