2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:30

Sanding paper is most in demand when working with wood material. Since wood has a rough surface, craftsmen almost always use just such a thing as emery to remove it. What is it? Sandpaper or sandpaper is an abrasive material, the main purpose of which is to give perfect smoothness to almost any surface.

Paper-backed emery

There are quite a few types of sanding paper. However, only a few of them are the most popular. The most used were emery on paper or fabric basis.

If we talk about the paper basis of this thing, then it is most often characterized by a fairly high density of the material. This is a very important parameter, since it will determine what mechanical damage the paper can withstand. In order to increase the service life and range of use, sometimes the sanding paper can be made with a waterproof base.

Advantages of this type of material:

- low material cost, especiallywhen compared to the extra grinding attachments that are sold on the drill;

- using this type of sandpaper, you don't have to worry that the base will be lengthened in the process;

- Paper-backed sanding paper can be coated with less abrasive during production.

However, there are also disadvantages, which include poor wear resistance, as well as low strength inherent in paper.

Fabric base

For the production of sanding paper with such a base, cotton is most often used, which is pre-treated with a special resin. It is because of this method of production that the fabric emery is characterized by increased resistance to water, improved flexibility, and is also characterized by a rather high strength.

The disadvantages of such a sanding skin include the fact that cotton tends to lengthen during operation. The second disadvantage is the higher cost compared to other bases, since cotton itself is more expensive, in addition, a special resin is needed for production.

It should be added that speci alty stores currently sell combination sanding papers. This emery is based on paper and fabric materials glued together.

Types of emery according to the method of applying grain

Sandpaper differs not only in the base, but also in the type of grinding grain used in the creation.

- The first type is paper with an open fill. During the production of this type of paper, the grain is sprayed in such a way as to cover up to 60% of the entire area of the skin. The advantages of this class include the fact that during operation it will not be clogged with debris due to the presence of large gaps between the grains of the abrasive. Most often, this type of emery is used for processing wood coatings or surfaces with medium density.

- The second type is a closed filling. This type of paper assumes that the entire basis of the skin is covered with a dense layer of grain during production. Using this grade of sandpaper is great for hard surfaces, but it needs to be handled with care as it clogs very quickly.

Abrasive grit for sandpaper

Today, different abrasive grains are used to produce such paper or drill bits. On this basis, 4 different types of material can be distinguished:

- Ceramic abrasive. This type of abrasive is one of the hardest, and therefore it is used for rough processing of wood material. It is produced in the form of special tapes.

- Silicon carbide. This type of grain is characterized by low strength indicators, as well as medium wear resistance. The scope of this material is grinding body metal, fiberglass, etc.

- Alumina. This type belongs to the very fragile, as it breaks very quickly under mechanical stress. Howeverthis disadvantage can also serve as an advantage, since if it breaks, new edges will form for grinding, which means that the emery can be used much longer.

- Garnet. Most often, paper with such an abrasive element is used to process different types of wood. This type of abrasive is considered one of the softest, and therefore its wear resistance is very low. In order to work with it, you need to have a lot of patience, since the process of grinding with such paper is very laborious.

Sandpaper marking

The designation of the sanding paper is regulated by GOST. In this document, grain is indicated as the main parameter, which is denoted by the letter P, and the limits of this parameter are numbers from 12 to 2500. It is important to understand that the larger the specified number, the smaller the grain size on the paper. It is also worth noting that in some former Soviet republics GOST USSR is used. In this case, the number 20-N will be indicated on the marking. In this case, it is important to know that tens of microns of grinding are indicated. If you need to specify a simple number of microns, then the marking will look something like this: M20. An approximate classification of types of sanding skins looks like this:

- for the most rough processing of the material use emery type P22, P24, P36 80-H, 63-H, 50-H;

- for simply rough surface treatment, grinding marked P40, P46, P60 40-H, 32-H, 25-H;

- in order to carry out the primary grinding of the desired surface, paper is usedgrades Р80, Р90, Р100, Р120 20-Н, 16-Н, 12-Н, 10-Н;

- in order to complete the grinding of the material and give it perfect smoothness, you must use sandpaper brand P150, P180 8-H, 6-H.

Sanding paper size

The size of the sandpaper is determined depending on its grain size. Emery with a grain index of 50 has a width of 720, 750, 800, 850, 900, 1000. This indicator is measured in millimeters. Paper with such parameters of width and grain size is produced in rolls 30 meters long. It is worth noting that with P50 and a width of 1250 mm, the length of the roll is reduced to 20 meters. For sanding paper, GOST 6456-82 defines all standard sizes, production and acceptance rules.

Production

The production technology of this product is the method of applying the abrasive to the base. There are several methods for performing this operation. This can be a mechanical method of application or a variant using an electric field. Each manufacturer of sanding paper chooses which method to apply the abrasive. It is also worth noting that the choice of connecting elements will also be an important factor in the production. They may be of various brands or types. Also, the strength and mode of operation of the abrasive skin will depend on the type of bond.

Recommended:

The size of the dollar in millimeters. Do banknotes vary in size?

What is the size of the US dollar in millimeters? Does the size of a banknote depend on its denomination? What is the rarest currency in the United States? Why is 1 dollar the most common in the world, what is the reason for this? Circulation of the monetary unit outside the country and within it

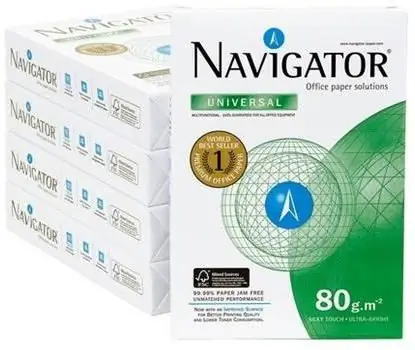

How many packs of A4 paper are in the box? Paper types, density, packaging

The main consumers of office paper are private and public institutions in which there is a large document flow. In order to correctly calculate how much money needs to be allocated for its purchase, you need to know the amount of spending and understand how many packs of A4 paper are in the box

How to choose the right business card size, paper and design?

This article explains how big a business card should be, what paper it can be printed on, and how to choose the right design to reflect the essence of your business

History of the creation of paper. Paper production

The article talks about how far paper has gone to reach its current prevalence. What was used before its appearance, what materials it was made of - all this is described in the presented material

How to choose the grit size of the grinding wheel? Marking and photo

Today, such an operation as metal grinding is used quite often. In order to successfully carry it out, it is necessary to carefully select the grain size of the grinding wheels. To do this, you need to know the markings, as well as what the granularity is