2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:31

Sanding sponge, consisting of abrasive materials, designed for processing almost all materials. Processing is usually understood as grinding and polishing the surface. Since in some cases a different degree of processing is required, sponges also come with abrasives of different hardness, with different grain sizes, and different shapes.

General description of sponges

If we talk about grinding sponges, then among all abrasive materials this type is considered the softest, most gentle. As a raw material for the manufacture of such products, soft porous materials are used, which are coated with abrasives. The main application of such devices is light sanding of wood coating, varnish, primer, paint. Here it is worth saying that the abrasive layer can be one-sided, two-sided and four-sided. Silicon carbide sponges are commonly used as an abrasive.

Sponges with different layers

Start with a single-sided sanding pad. It is considered the easiestapplication. Its main advantage among others is a rather small layer thickness, which makes its use more convenient. This is the most relevant property in the event that it is necessary to process surfaces with strong cuts, bumps and other imperfections.

The next type is an abrasive sponge with a double-sided layer. Experts note that it will be convenient to use this type of grinding sponge, regardless of which surface needs to be processed. It works best on profiled surfaces in almost any material.

The last type is a four-sided sponge. This type of abrasive is used quite widely if it is necessary to work with wood. Sanding pads for wood with four-sided abrasive are excellent even for intermediate work, when priming or varnishing a wooden surface. Most often, a sponge with medium hardness is already used for such work. Its advantage over a more rigid one lies in the presence of a slight plasticity, which greatly simplifies the work process.

Using sponges

To date, the grinding abrasive sponge is the most widely used in the manufacture of cabinet furniture. Without the use of such a device, it is impossible to obtain a perfectly flat surface that furniture should have. This is very important, because nowadays the requirements for the appearance of furniture are quite high. The use of a grinding sponge allows you to get not only perfectly smoothsurface, but also save work time and improve processing quality.

The lifespan of the sponge and its ease of use have led to the fact that they are used almost everywhere. To date, any finishing type processing cannot do without the use of such a sponge or without an abrasive of similar quality and parameters.

Properties and structure

As for grinding tools, they usually consist of three components: an abrasive, a substrate and a bonding element. We talked about the abrasive material, it's time to pay attention to two other important components.

The second element is the backing. It is usually used as a paper or fabric base, on which the abrasive material is glued. Cloth applications are more common for sanding belts, rolls, and more. Paper is used for sanding sheets or discs. It is also worth adding that other bases are periodically found, for example, polyester. The ZUBR company has become a good representative of a quality product. Grinding sponges of this company are of high quality. The base is elastic EVA. Aluminum oxide and synthetic resin are used as a binder.

A bonding element for a sponge is a layer of some adhesive substance that can hold an abrasive substance.

Another very important parameter is graininess. When choosing a sponge, it is very important to correctly select this characteristic for the requiredmaterial type. This indicator is the most important, especially when choosing a sponge for wood processing, for example. The ability of the material to qualitatively process any material depends on the graininess and its gradation.

Recommended:

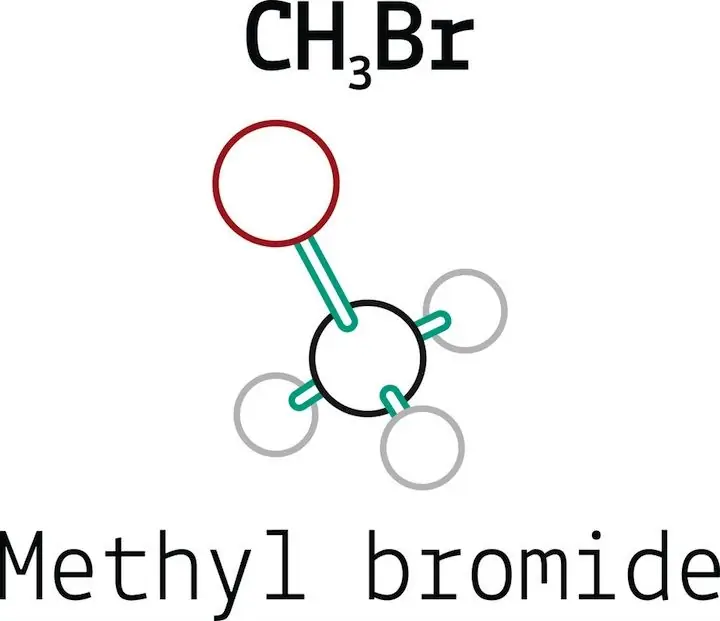

Methyl bromide: properties, production, purpose and application

Methyl bromide is a fumigant used against a wide range of pests including spiders, mites, fungi, plants, insects and rodents. Introduced as a pesticide in 1932. Methyl bromide fumigation is used to fumigate agricultural commodities, grain silos, mills, ships, clothing, furniture, and greenhouses

Cement slurry: properties, preparation rules, composition, compliance with GOST requirements, purpose and application

During the drilling process, special solutions are used to flush out cuttings and products from the development of local rock. This operation is necessary to increase the efficiency of the mechanical impact of the drilling rig and to clear the bottom hole. Washing out is carried out using cement slurries, which are prepared using special technologies

Titanium carbide: production, composition, purpose, properties and applications

Titanium carbide: the history of the discovery of this compound, chemical and physical and mechanical properties. Description of how to obtain it. Part coating, carbide steel fabrication and other titanium carbide applications

Two-component polyurethane sealant: definition, creation, types and types, characteristics, properties and nuances of application

With long-term and high-quality sealing of seams and cracks, polyurethane two-component sealants have found their wide distribution. They have high deformation and elastic properties, therefore, they can be used as butt sealants in the field of repair and housing construction

What is fabric made of? Classification of fabrics by type of raw materials, properties and purpose

Using fabric in everyday life, one does not even have thoughts about how significant this invention was for mankind. But without fabrics, life would be uncomfortable and unthinkable! A person is surrounded by tissues in all his life activities. When did the first fabric appear, and what is it currently made of? Let's talk about it in the article