2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:47

Cutting machines are used by professional builders for wood processing. Modern modifications are produced with adjustable spindle units. All this allows you to more accurately control the angle of cut. Some modifications are made with milling blocks. They are distinguished by high power. Flywheels are used to adjust the beds. Some modifications are found with pendulum devices. There is a good wood trimming machine (market price) of about 250 thousand rubles.

Hand-held devices

For a small workshop, a compact manual wood trimming machine is great. It includes a small caliper, a spindle assembly, as well as a bed. Directly the saw area is regulated by the handle. Such devices are well suited for processing oak products. If necessary, the modification can be made independently, and the frame is easiest to install from cast iron. Modifications are characterized by low performance. However, it is worth noting that models can be made with adjustable rails.

Low power machines

Low-power woodworking equipment is suitable for cutting short workpieces. Also devices are used for milling. However, it is worth noting that there are modifications with driven and non-driven units on the market. In the first case, the cutting speed can be adjusted. In this case, the height of the workpiece is adjusted separately. Non-drive modifications are simpler and characterized by ease of use. They use motors on terminal boxes with contact anchors. The maximum power of such modifications is 4 kW. For small workshops, they are well suited. However, it is worth remembering that the angle of cut is quite difficult to adjust with them.

Industrial modifications on the market

Industrial wood cutting machines are characterized by high productivity. Calipers in most cases are made with pendulum mechanisms. Some modifications are equipped with panels to protect the operator. It is also worth noting that there are modifications with a double spindle assembly on the market.

Adjustment of the workpiece in height is carried out by means of long guides. Also, industrial modifications have a workpiece fixation handle. Some models are able to boast of a high-quality collector-type motor. Drive units are usually used with a belt adapter. Modifications are able to work with large workpieces.

Pendulum mechanisms

Cutting machineon wood (pendulum) is mainly produced with a single-phase motor. The models have two pairs of supports. In this case, the rotor is used on the collector. Some modifications are available with a short spindle. The fitting in the devices is made with a large tip. Pendulum modifications are suitable for all milling work. It is also worth noting that the models are used on movable and fixed type beds.

Some devices are found with a frequency of over 3 thousand revolutions per minute. They use an adjustable caliper and provide high conductivity. Controllers are very rarely installed on modifications. It is also worth noting that the models are not suitable for longitudinal cutting of wide workpieces. Guides are most often mounted above the spindle and take up a lot of space. As a result, the devices are large and inconvenient to transport.

Automatic woodworking equipment

Automatic wood trimming machines are produced with controllers of different frequencies. Many models are equipped with collector motors that can operate in different modes. It is also worth noting that there are devices with additional stops. The blanks are stacked on platforms. Spindle blocks are quite often used on belt drives. Knobs and flywheels are used to adjust the height of the work area. There are also modifications for two fittings on the market. They have very wide beds.

Modification for 3 kW

Woodworkingequipment of the specified power is suitable for turning work of varying complexity. Modern modifications are made with blocking collector motors. Spindles are used with and without locks. Modifications for milling products are distinguished by high-quality adapters. Their guides are installed with racks. A cover is used to protect the equipment. Also on the market are devices with workpiece clamps that can be adjusted using the module.

Assembling a 5 kW model

The 5 kW wood cutting machine is suitable for sawing oak bars. Also, devices are actively used for milling boards. Many modifications include commutator motors with belt drives. There are also modifications on the controllers that are able to accurately cut wood at an angle.

When choosing a modification, special attention should be paid to the guides. As a rule, they are mounted on stands at the top of the frame. There are also devices with a lower caliper. They are characterized by high performance. However, they have a small working surface.

10 kW devices

10 kW wood cutting machine is quite common in industry. In this case, special attention is paid to the security of the operator. Rotary boxes directly are produced with a terminal block. It is also worth noting that there are gear devices on the market that allow you to adjust the speed of milling the product. Modifications with automatic control are expensive. When choosing a modification, you should pay attention to the control angle. Old models on flywheels are not able to provide high-quality cut wood.

Upper Caliper Device

Top-slide machines provide good machine performance in the first place. However, there is a lot of pressure on the frame. Shafts for modifications are used in small sizes, and they have a very high frequency rate. The shaft is capable of making more than 2500 revolutions per minute.

Fitting devices for machines of this type are used with extended rods. The stems can be installed with or without a lining. There are also many modifications on the drive units on the market. For professional cutting of wood, only models on controllers are suitable. When choosing a device with an upper caliper, you should look at the frame of the product. The bed must be made with stops of great length. All clamps must be fixed at all angles.

Lower caliper model

The wood cutting machine with the lower support shows itself well when sawing wide logs. Many models have a double spindle, which is powered by a shaft. It is also worth noting that the market is full of modifications on collector motors. They work with a frequency of at least 2300 rpm. There are also devices with blockers.

Directly rotors are used with protection systems. Professional machines can be equipped with dust collectors. Racks in devices are made of cast iron and steel. Rails are attached both above and below the frame.

Two quill model

The wood trimming machine with two quills is suitable for turning products of various shapes. According to experts, manufacturers provide modifications mainly with an upper caliper. Directly the spindle is installed above the platform.

The saw blade is quite often guarded with a plate to protect the operator. In some cases, collector motors are used, which can be powered by modulators. Thus, the saw process can be controlled from a distance. Modern modifications are distinguished by high-quality calipers with overlays. Adjustment pins come in different lengths. To control the platforms, controllers are used, which are configured by the handle. It is also worth noting that some manufacturers make devices with small inserts that are not suitable for large workpieces.

Recommended:

Wood processing technology and production of wood products

Wood is an unusual and especially valuable material. For all its familiarity, it has an amazing set of technical and physical properties that a person cannot repeat with the help of synthetic substitutes. This is due to the extensive use of blanks made of natural wood in a variety of industries. Modern wood processing technologies and the production of wood products in general make it possible to provide people with furniture, building materials, decorations, utensils, etc

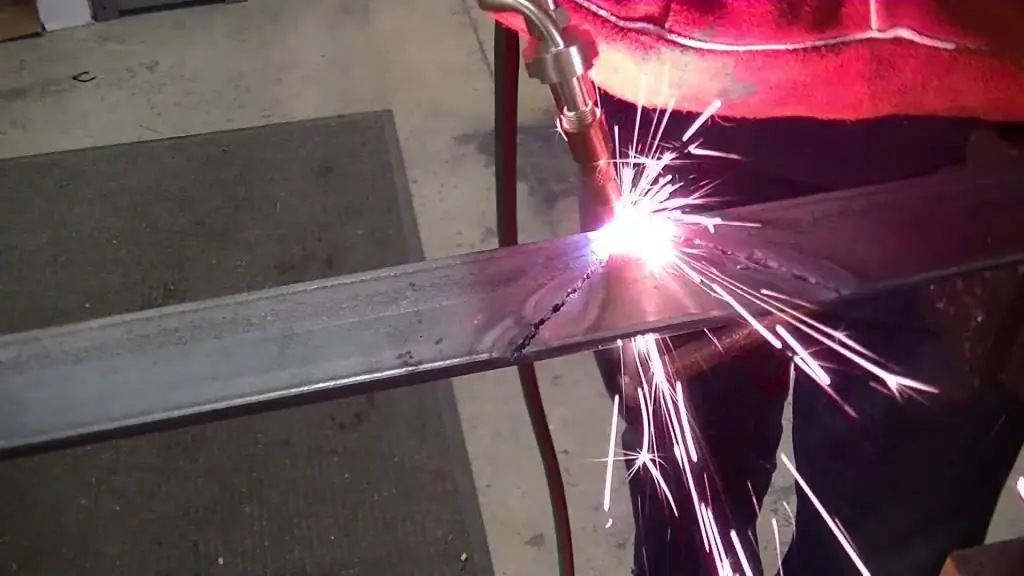

Oxyfuel cutting of metal: technology, necessary equipment, safety precautions

Oxy-fuel cutting of metals (in the literature you can find the term "oxy-fuel cutting") is actively used in industry for cutting sheet material from steel and other alloys into workpieces of the required length. The article contains information about the technology itself, about the necessary equipment and basic safety precautions for oxygen cutting of metals and other materials

Types of metal cutting: an overview of modern technologies and equipment

One of the most common metalworking operations is cutting. It is a technological process during which a sheet or billet is divided into parts of the desired format. Modern types of metal cutting allow this operation to be performed with high accuracy and a minimum amount of scrap

Cutting mode for milling. Types of cutters, calculation of cutting speed

One of the ways to finish materials is milling. It is used for processing metal and non-metal workpieces. The workflow is controlled by cutting data

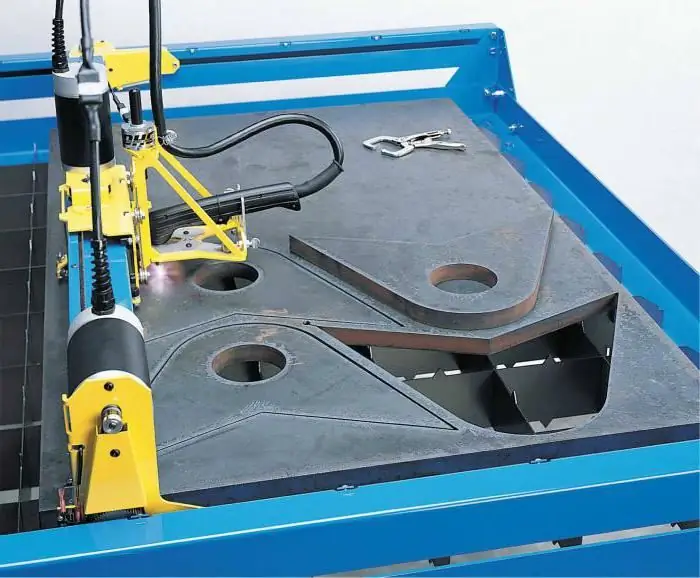

Metal cutting machine. Plasma metal cutting machine

The article is devoted to the apparatus for cutting metal. The technology of plasma cutting, as well as the device and features of the equipment are considered