2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

According to environmental studies, up to 40% of electricity and heat generated in the Northern Hemisphere is used to heat industrial, residential and other facilities. This leads to the fact that high-quality thermal insulation of buildings brings significant benefits in terms of financial savings. Among other things, this allows you to achieve a comfortable stay. The role of one of the most common heat insulators is foam, it is also called polystyrene foam, or EPS.

Vapor permeability

The vapor permeability of foam is quite low. In practice, this means that an obstacle in the form of polystyrene foam will be located on the path of steam from inside the house to the outside. Outside buildings, the temperature is often lower than indoors. Therefore, the steam will turn into condensate, as a result of which water will accumulate in the areas where the thermal insulation meets the wall structure. This leads to the risk of getting wet materials that are nearby.

In order for the vapor permeability of the foam to not become a minus when using this insulation, you should correctly calculate the dew point and determine which insulation thickness to choose. In this case, the dew point can be carried out beyond the limits of the installed material. A reasonable solution in this matter is the installation of a ventilated facade. The vapor transmission characteristics of a heat insulator are not considered in isolation from the details of a particular design. It is important to consider what the walls are made of, how high the foundation is, and whether the installation of steam and waterproofing was carried out.

How to make vapor permeability a plus

The vapor permeability of the foam is 0.05 mg/(m year Pa). In this regard, its use can lead to the formation of mold. In general, this characteristic is not only a negative, but also a positive feature. The advantage is that when laying thermal insulation there is no need to create a vapor-permeable barrier. But a minus may appear if the installation technology has been violated. Under the foam, as mentioned above, moisture will form, which will certainly lead to the destruction of both the construction material itself and the insulation layer.

The vapor permeability of foam plastic will not affect the microclimate of the premises in any way if it is installed outside the building. You should not assume that on sale you can find polystyrene foam with different vapor permeability. This characteristicremains the same, regardless of density and foam. This indicator is similar to the log cabin of oak or pine.

Structure and composition

Styrofoam is a white material with a foamed rigid structure, in which 2% polystyrene and 98% air. For manufacturing, a technology for foaming polystyrene granules has been developed. These microscopic particles are treated with hot steam in the next step. This procedure is repeated several times, which allows to reduce the weight and density of the material. The prepared mass is dried to remove residual moisture. The raw material is in the open air in drying tanks. At this stage, the structure takes on its final shape.

The granules have a size that ranges from 5 to 15 mm. When they are dried, they are given the appropriate shape. Pressing is carried out on plants or machines that turn the material into something like a compact form of packaging. As soon as the foam is pressed, it is exposed to hot steam, as a result, blocks with certain parameters are formed. They are cut to size with a tool. Sheets may have non-standard sizes. The sheet thickness varies from 20 to 1000 mm, while the dimensions of the boards can be from 1000 x 500 mm to 2000 x 1000 mm.

Basic Features

When you know what the vapor permeability of the foam, you can ask about other characteristics, as well asfeatures. Among others, it should be noted:

- low thermal conductivity;

- high sound and windproof properties;

- low water absorption;

- durability;

- strength;

- resistance to chemical and biological attack.

As for thermal conductivity, it is an undeniable advantage of the foam. This is due to the fact that the cells in the base have the shape of a polyhedron. Their size reaches 0.5 mm. The closed cell cycle reduces heat transfer and limits the penetration of cold.

Sound and windproof

The thickness and vapor permeability of the foam - this is not all you need to know when buying material. It is important to take an interest in sound and windproof properties. If the walls are insulated with foam, they will not need wind protection. The soundproofing of the building will be improved. Thus, the soundproofing properties are due to the cellular structure.

In order to provide high-quality insulation from external noise, you will need to lay a layer of material, the thickness of which is 3 cm. If you increase this figure, you will be able to achieve better sound insulation. The vapor permeability of the facade foam was mentioned above. However, this characteristic is not the only one you should be aware of. It is also necessary to take an interest in durability. The plates of this insulator do not change their physical properties for a long time. They are ready to endure high pressure without collapsing ordeforming. An excellent example of this is the construction of runways, where polystyrene foam has long been widely used. The degree of strength depends on the thickness of the boards and the correct installation.

The vapor permeability of 25 density foam remains the same as mentioned above. The first indicator does not depend on other characteristics in any way. But before purchasing this heat insulator, it is also important to know about resistance to chemical and biological influences. The plates are resistant to aggressive environments, solutions of alkalis, s alts and acids, sea water, gypsum and lime. Expanded polystyrene can come into contact with bitumen, cement, water-soluble and silicone paints. Substances can affect the canvas only with prolonged exposure. This applies to materials containing vegetable and animal oils, as well as diesel and gasoline.

The vapor permeability of foam and extruded polystyrene foam has been mentioned above. Before buying this material, it is also important to know that you can use the insulation as a building material, eliminating contact with aggressive chemicals, including saturated hydrocarbons and organic solvents.

Fire safety

Vapor permeability and fire safety of polystyrene are one of the important characteristics. Modern building materials must meet fire safety requirements and show resistance to open flame during operation. Styrofoamdoes not support combustion and flashes at a temperature that is 2 times higher than that of wood. Energy during the combustion of foam plastic is released 8 times less than during the combustion of wood. This suggests that the temperature of the fire will be significantly lower.

What to watch out for

Styrofoam can ignite only during direct contact with the flame. Upon termination of such contact, the foam self-extinguishes within 4 seconds. These indicators characterize it as a fireproof material suitable for construction.

Application

The air permeability of foam is quite low, making it unsuitable for indoor use. But the structure of the material is cellular, which makes the material a universal sound and heat insulator in the field of construction. Expanded polystyrene is used to make industrial products such as foam sheets, pipe insulation and foam shells. The material fills the compartments of the vessels, which increases their buoyancy. Styrofoam is used to make bibs, life jackets and floats. It is used to transport donor organs, make medical packaging, and is used for other needs in medicine.

PPS has found its wide application in construction and decoration, it is used as a fixed formwork. It also serves as a heat insulator in instrument making. It can be used as packaging for expensive and fragile goods. It acts as a substrate for food products and as a raw material for the manufacture of disposable plates. FromStyrofoam is often made decorative items. It can be exterior and interior decoration of buildings, as well as premises for various purposes. It is used to make ceiling tiles, skirting boards, Christmas decorations, architectural decor, and garden decor.

Foam Classification

Styrofoam today is known in many varieties, among them should be highlighted:

- polystyrene;

- polyurethane;

- extrusion foam;

- polyvinyl chloride;

- extruded polystyrene;

- polyethylene foam.

PPS can be made by pressing or non-pressing method. It is not difficult to distinguish between these materials. The press variety is made by the method of strong adhesion of granules, so such webs are more difficult to break. Extruded polystyrene is almost the same as non-press foam. The material has disadvantages, expressed in the fact that there are cavities between the granules where water vapor can penetrate. At sub-zero temperatures, moisture accumulates there, which leads to the gradual destruction of the material. In this regard, extruded foam wins somewhat. In appearance, it has a homogeneous structure. Among the advantages of this material should be highlighted:

- long service life;

- greater strength.

Polyethylene foam is very flexible. It often takes the form of translucent sheets of various thicknesses that are flexible. The most used in everyday life is polyurethane foam. In the people it is called foam rubber and is differentelasticity.

Recommended:

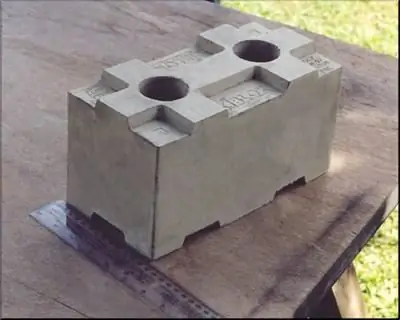

Foam block: foam block dimensions, history of appearance and application prospects

Each movement of the bricklayer is performed at a certain speed. An ordinary clay brick weighing about 3 kg or a large foam block of the same mass will be installed in the wall in the same time. But the dimensions of the foam block are eight or even twelve times the size of a brick, which dramatically increases the speed of masonry. Another important advantage of a light and warm building material is that it requires an adhesive rather than a complex cement-sand mortar

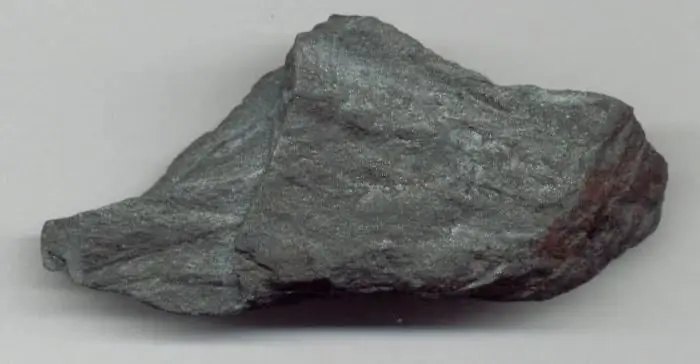

Types of cast iron, classification, composition, properties, marking and application

The types of cast iron that exist today allow a person to create many products. Therefore, we will talk about this material in more detail in this article

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document

Organizational structure of Russian Railways. Scheme of the management structure of Russian Railways. Structure of Russian Railways and its divisions

The structure of Russian Railways, in addition to the management apparatus, includes various dependent divisions, representative offices in other countries, as well as branches and subsidiaries. The head office of the company is located at: Moscow, st. New Basmannaya d 2

Steel: composition, properties, types and applications. Composition of stainless steel

Today, steel is used in the vast majority of industries. However, not everyone knows that the composition of steel, its properties, types and applications are very different from the production process of this product