2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

As practice shows, conventional gating systems in a modern design allow for the final shaping of the finished product with clear contours. In some cases, special designs are used when the metal undergoes a long and complex transformation. These units are equipped with a circular manifold to improve filling conditions.

Side modifications

Side gate systems are equipped with feeders that are located at right angles to the gate. This type is often used in single and multi-slot molds.

When approaching the working cavity, the feeder has a reduced thickness, aggregates with the inlet element, the cross section of which affects the amount of metal passing through the mold cavity. In side-type feeders, the raw material moves along the parting plane with subsequent filling of the lower part of the working chamber. In this case, the ventilation ducts are blocked, which makes it difficult to remove air. As a result, side runner systems are most effective when producing shallow blanks.

If you move the cavity into the moving part of the unit, metal coming under pressure will also prevent removalair bubbles from the depths. It is worth noting that when casting parts with large central rods located perpendicularly, a number of defects may appear.

Features of the side sprue

The placement of the side feeder along the tangent line allows you to level the frontal impact and turbulence. The casting has a wide element that is set perpendicular to the core, and there are also large air connections. As a result, there is no air porosity and oncoming jets.

With tangential sprues, annular casting is obtained with the highest quality, provided that the width of the part is commensurate with that of the work item. It is irrational to use such a mechanism when casting ring blanks with a stepped diameter and solid parts. This is due to the fact that when the metal rotates, it swirls, and this negatively affects the filling of the central part, forming gaps in it. To solve the problem, a sprue with a wider diameter is used.

Calculation of the gating system requires taking into account the width of the intake manifold and its placement. These factors affect the quality of the casting. It should be noted that when the sprue is located near the wide part of the workpiece, the metal will flow in a wide stream, swirling and prematurely filling the ventilation slots. If the system is mounted on the narrow side of the part, the material will flow along the walls without significant turbulence.

Central runner systems

Central variations are used for casting slabs witha free central field (frames, rings) is provided. They are also used to produce box-shaped and cylindrical parts with an open center cavity.

This design feature allows you to mount the sprue in the center of the axis from the end side. In this case, several feeders can be used. Central holes are used in the production of parts with cavities, the bottom of which has a hole. A rod is passed through it, transforming into a divider. This element can pass strictly in the center or with an offset, which makes it possible to place the mold in the cavity asymmetrically to the running element.

Among the advantages of center runner systems for injection molding are the following:

- It is possible to fill the working cavity with several feeders without the formation of oncoming metal jets.

- The design has the same temperature regime of all working surfaces, which ensures the exclusion of surface deformations.

- Guaranteed a significant reduction in the path of the metal without additional jet from the compression chamber.

- Provides equal direction of metal inflow and air extraction.

For the correct operation of the unit and the elimination of turbulence, the jet must be directed parallel to the center rod and the mold walls.

Using sprues

The devices under consideration are used exclusively in forms with one working socket. Casting thin-walled blanks requires the installation of severalfeeders. To work with a thick-walled part and weak streamlining, one element will be enough. It is installed tangentially with the inlet compartment, which allows you to remove air impurities as much as possible when metal enters from one side.

Processing of large workpieces of box-shaped and body configuration is carried out using several feeders of the central type. This allows you to provide power to all remote areas of the working cavity, as well as to exclude the occurrence of a continuous jet that causes delamination of the raw material. The total value of the feeders increases, and the advantages of the central casting mold appear if the cross section of the input element is exceeded so much as to provide power to the working cavity without interruptions in the liquid metal jet at each feeder.

Direct Feeders

Central feeders without dividers are used for casting structures, the configuration of which does not allow the installation of side counterparts. In this case, the elements of the gating system are mounted directly on the part, they also serve as a feeder. It is reasonable to use direct modifications for casting thick-walled compact blanks, which are processed at low speeds by large-section feeders.

Filling when working in such conditions is not particularly difficult. The main emphasis is on sealing the metal with final pressure. Optimum results in the process are obtained when the load on the raw material is not removed before the opening period of the working mold (chamber of the pressedtype).

Circular collector models

Similar gating systems for steel castings are used when it is impossible to provide sufficient filling of all remote parts of the working chamber with one feeder. The main purpose of the unit is to synchronously supply metal to all peripheral compartments, after which the raw material enters difficult-to-feed points using several inlet elements.

This design is appropriate in the presence of remote parts from the sprue that do not fit into the standard overall dimensions. In addition, such a configuration is suitable for casting lattice blanks, which are hampered in manufacturing due to the thin-walled structure. This is especially important if rods are installed near remote compartments. When the grating ebbs, the meeting of two jets in narrow pockets practically does not experience vortex obstacles, in contrast to a similar process in large-volume cavities.

Operation

Circular commutator casting systems are used to machine small, thin-walled gear wheels that have a wide pitch and tribok. Feeders with a small cross section and a thickness of about 0.5 mm are supplied to each tooth from the collector.

The use of directional feeders makes it possible to expel air from the metal even in hard-to-reach and poorly ventilated places. They are optimally suited for the smelting of blanks in box and shell configurations. The design avoidscausing frontal impacts and excessive swirl.

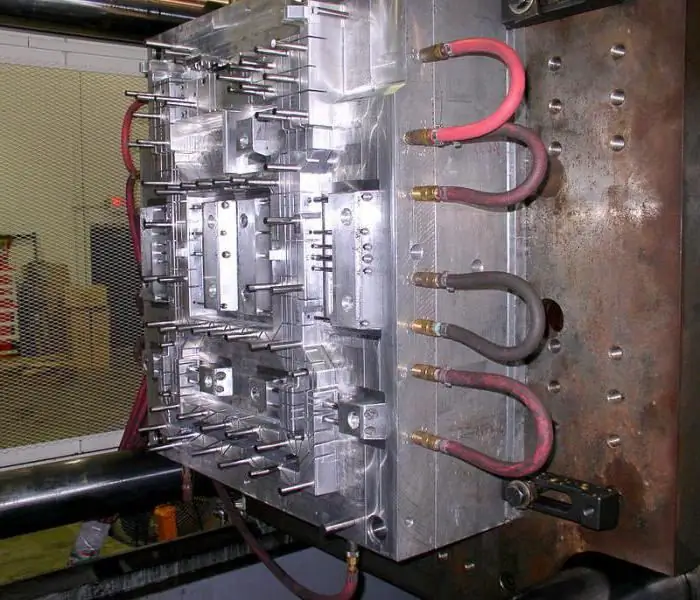

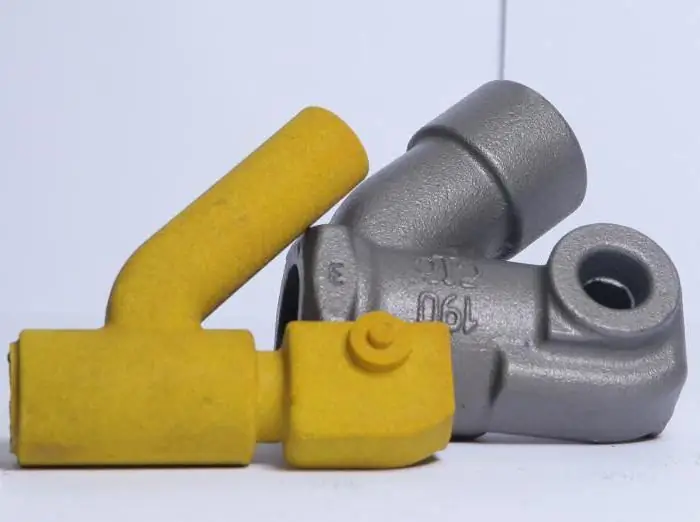

Press form

This foundry element is a complex device for producing metal, polymer and rubber products of various shapes. The unit is used for casting a variety of products under pressure from injection molding machines. The mold can be of several types:

- Mechanical type.

- Semi-automatic or automatic.

- Fixed and removable mounting.

- With horizontal and vertical split planes.

The assembly includes a fixed matrix and an active part. The forming cavities of these parts are designed in a reverse way, which makes it possible to provide the required imprint of the workpiece. Raw materials are supplied by a gating system, and the temperature is controlled by water circulating in the cooling circuit.

Recommended:

Hydraulic system: calculation, scheme, device. Types of hydraulic systems. Repair. Hydraulic and pneumatic systems

The hydraulic system is a special device that works on the principle of a liquid lever. Such units are used in the braking systems of cars, in loading and unloading, agricultural machinery and even in the aircraft industry

Casting in silicone mold: equipment. Vacuum casting in silicone molds

For the manufacture of a small number of plastic blanks, vacuum casting into silicone molds is most often used. This method is quite economical (making a metal mold requires more time and money). In addition, silicone molds are used repeatedly, and this also significantly reduces the cost of production

Casting mold: features, technology, types

One of the most important processes in the industry is the process of casting various parts, raw materials and other things. However, in order to successfully produce the desired thing, it is necessary to make a mold for it, which largely determines the final result

Shell mold casting: basic mold making operations

Currently, the industry is seriously developed and many different methods are used in casting. One such method is shell casting

Types of accounting. Types of accounting accounts. Types of accounting systems

Accounting is an indispensable process in terms of building an effective management and financial policy for most enterprises. What are its features?