2026 Author: Howard Calhoun | [email protected]. Last modified: 2025-01-24 13:10:43

Intensive development of industry contributes to changing the working conditions of employees of enterprises. With regard to manufacturing industries, we can talk about the problems of air purification, which is polluted by the smallest particles of waste products. The tasks of aspiration for woodworking are particularly acute, since it can not just be about chips and sawdust. Virtually every plant of this type, during mechanical processing, releases wood dust, which is dangerous to the lungs of people due to its adsorption capacity.

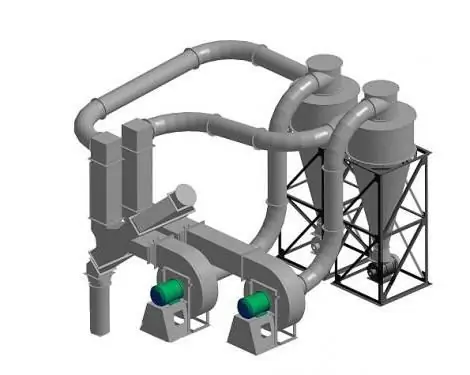

Aspiration as a kind of pneumatic transport systems

According to technical requirements, all woodworking enterprises have intrashop or intershop transport in their communication infrastructure. We are talking about pneumatic transport channels, which can be provided by traction elements, drive systems or autonomoussources of energy supply. Aspiration systems just belong to such units, performing the tasks of timely removal of the aforementioned dust and chips in workshops where woodworking equipment is used. Aspiration as such is a complex of technical means and stationary communications, and the requirements for it are made on the basis of the regulatory sanitary and hygienic regulations.

Varieties of aspiration systems

Suction device configurations may be different depending on the application conditions and technological requirements. The most common types of aspiration for woodworking are:

- Direct-flow centralized. Several channels from different woodworking machines collect the dust-air mixture into one stream and send it to the separation apparatus, where air is separated from mechanical impurities. Clean air is sent to the atmosphere, and particulate matter is sent to special dust collectors.

- Recirculation-centralized. The principle of operation is generally similar to the previous system, but with the difference that the purified air is not thrown out, but is transported to the workshop. This filtration scheme has advantages, as it maintains the temperature regime, however, the return of recycled air negatively affects the quality of the renewal of the local air environment.

- Direct-flow autonomous. If in the previous cases, contaminated flows are collected in one channel and subjected to general cleaning, then in once-through systems for each machine there is an individual filtration apparatus that emitsair to atmosphere.

Ventilation systems

Direct-flow aspiration systems operate in parallel with supply and exhaust ventilation. This combination is used when the purified air is released into the atmosphere. Moreover, the task of ventilation is not only to update the air content, but also to improve other microclimatic indicators inside the workshop. These can be characteristics of pressure, temperature and humidity. If woodworking suction hoses operate on the principle of a recirculation principle with a return flow, then the supply and exhaust system performs the task of passive background cleaning. The fact is that recirculation in any case does not provide 100% removal of pollution and the returned air will contain harmful mechanical impurities by 1-3% - about 6 mg / m. In this case, the ventilation function is just useful, which regularly refreshes the air environment, eliminating the remnants of woodworking products. And again, it is worth emphasizing the effects of improving the microclimate with an increase in humidity and pressure stabilization.

Air ducts in the suction infrastructure

Both the operation of the suction equipment and the provision of ventilation functions require a network of air ducts. Industrial pneumatic transport is usually served by pipelines with a circular cross section and a throughput of about 23 m/s. As for the material of manufacture, galvanized metal, metal-plastic and plastic can be used.composite structures. The choice of material depends on the operating conditions at a particular enterprise. By design, air ducts for aspiration of woodworking can be divided into spiral and straight-seam with flanged and welded joints. The type of fastening and formation of joints affects the loss factor, which is important from the point of view of the tightness of the content of contaminated streams. According to the leakage coefficient, three categories of air ducts are distinguished:

- Lower class - 1, 3 (l/s)/m.

- Middle class - 0.4 (l/s)/m.

- Top class - 0.15 (l/s)/m.

Diameter of channels varies from 140 to 1250 mm. Accordingly, the choice for this indicator depends on the original process nozzles. The large format is used for supply and exhaust ventilation, and the small one is used for general channels for collecting dust and chips from machine tools.

Wood dust extraction systems

In addition to transporting polluted and clean streams, the tasks of direct air purification also play an important role. For this, cyclones and filtration systems are used. The former consist of two cylinders with an annular intermediate space, where the transition of clean air from dirty air takes place. Once in the cyclone, the air-material mixture begins to rotate, during which solid particles up to 10 microns in size are sent to the discharge opening. Aspiration filters for woodworking also separate dust from the air. Cassette corrugated and fabric devices are used in the form of bags, sleeves and cloths. Both types of filterswork effectively with fine dry contaminants. The purification rate reaches 99%.

Stationary shop floor aspiration systems

To work with large volumes of air-material mixtures, recirculation workshop units are used, which dump accumulated waste into special storage bins. The productivity of such equipment varies from 20,000 to 100,000 m3/h, and the capacity of the dust collector reaches 70 m3. The main operational advantage of workshop aspiration systems for woodworking is their outdoor placement and the possibility of organizing cleaning without the use of air ducts.

Homemade suction system

In the household for the workshop, you can limit yourself to arranging powerful forced ventilation. When working with one tool or machine, a point dust collecting machine with a dust collector is enough. But professional aspiration for woodworking with your own hands can only be realized as a full-fledged chip extractor, which will also capture large particles. Such a design can be implemented on the basis of an asynchronous four-phase motor that drives a powerful fan installation. From the materials it is necessary to provide thick chipboard panels for the structure, a set of membranes of various calibers for multi-stage purification of flows and plastic pipes through which the flows will be circulated.

Conclusion

Withouta high-quality dust collection and air purification system is indispensable even in the small conditions of a carpentry workshop. If we talk about specialized installations, then an aspiration system for BU woodworking can cost about 20-25 thousand rubles. It will be an analogue of an industrial cyclone or a ventilation dust collector with a powerful engine. Comprehensive provision of the workshop with new equipment with air ducts and intermediate filters can cost about 100-150 thousand rubles.

Recommended:

Hydraulic system: calculation, scheme, device. Types of hydraulic systems. Repair. Hydraulic and pneumatic systems

The hydraulic system is a special device that works on the principle of a liquid lever. Such units are used in the braking systems of cars, in loading and unloading, agricultural machinery and even in the aircraft industry

Woodworking enterprises and their place in the country's economy

Large woodworking enterprises were mainly located in Siberia - where the taiga grew, giving the main raw materials. At the beginning of the nineteenth century, there was a significant increase in production in this industry, but its material and technical base was still underdeveloped. Therefore, for the most part, the production of sawn timber prevailed, and complex wood products were still created by hand by handicraftsmen

Aspiration systems: calculation, installation. Production of aspiration systems

Aspiration systems are systems that are designed to purify the air. The use of these installations is mandatory at all industrial enterprises that are characterized by harmful emissions into the atmosphere

Visa and Mastercard systems in Russia. Description of Visa and Mastercard payment systems

Payment system - a commonality of methods and tools used for money transfers, settlements and regulation of debt obligations between participants in economic turnover. In many countries, they differ significantly from each other due to the diverse provisions in the levels of economic development and the characteristics of banking legislation

Corporate systems - enterprise management systems. Basic Models

The article discusses the concepts of "corporate enterprise management systems" and "corporate project management system". In addition, the basic models of CPMS are described