2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Production vibration poses a danger both to human he alth and to building structures, process equipment. Under the influence of mechanical vibrations, the wear of machines is accelerated, the period of time between their repairs is reduced, and the accuracy of measuring instruments and control equipment is reduced. Transmitted through solid foundations, vibration also affects other, non-production premises, and maintenance personnel. Assessment of harmful fluctuations is included in the system of sanitary and hygienic assessment of working conditions.

General concept

Production vibration occurs as a result of the mechanical vibration of working machines, the movement of fluids and other unbalanced influences. An increased level of vibration has a negative impact on human he alth, reducing its performance, and with prolonged exposure causes occupational diseases. Therefore, the issues of combating mechanical vibrations in sanitation are of particular importance.

Vibration can be transmitted to a person both directly through contact with equipment or tools,and indirectly - through the elements of industrial premises. The requirements for the control of this unfavorable factor and its maximum allowable values are set out in a number of regulatory documents (SN 2.2.4-2.1.8.566-96, SP 1102-73, GOST 12.1.012-2004, SanPiN 2.2.4.3359-16 and others).

Views

Classification of industrial vibration is made according to several criteria:

1. By localization:

- General. Such vibration affects the nervous, musculoskeletal, cardiovascular system, gastrointestinal tract (pain in the stomach or in the lower epigastric region). With prolonged exposure, vibration disease can occur - an incurable pathology.

- Local (local), transmitted to the limbs of a person when resting on a vibrating surface.

2. By origin:

- For local fluctuations: from hand powered or non-powered tools.

- For general vibration: Category I, II and III (described below).

3. Direction in space: X, Y, Z-oscillations. The most dangerous are those that are directed along the axis of the body.

4. Spectrum:

- Narrowband (the level of vibrations of one third of an octave to be controlled is 15 dB higher than in neighboring sections of the same width).

- Broadband (their spectrum is continuous for more than 1 octave).

5. Frequency:

- Low-frequency (<4 and <16 Hz for general and local vibrations respectively).

- Mid-Frequency(<16 and <63 Hz); o high-frequency (<63 and <1000 Hz respectively).

6. By duration:

- Permanent.

- Periodic (fluctuating, intermittent, impulsive).

Types of general industrial vibration

General vibrations by source are divided into 3 types:

- Transport (machines such as tractors, mine transport, combines, trucks, snowplows are most susceptible to them);

- Transport and technological (occurring when moving along the surface of industrial premises - excavators, cranes, floor filling machines for loading charge into the furnace, rolling stock for the construction and repair of the railway, concrete pavers and other equipment).

- Technological, arising from stationary equipment (machines, presses, pumps, fans, drilling, chemical and petrochemical installations and others).

Features

The main indicators describing various types of industrial vibration are the following:

- Circular frequency (number of oscillations per second). When measuring vibrations, the vibration spectrum is divided into frequency bands, for each of which the intensity is estimated. For this, octave filters are used, the nominal bandwidth of which is equal to one octave.

- Amplitude (maximum deviation) of vibration movement.

- The highest or rms value of vibration velocity and acceleration.

Sources

Production sources of vibration, according to the type of general vibrations, include:

- narrow-band - construction vehicles, trams, tractors, harvesters, trams, railway cars and locomotives;

- polyharmonic (changing according to a periodic law) - metal and woodworking machines, internal combustion engines, hydraulic turbines and generators, compressors, textile machines, vibroconveyors;

- random and polyharmonic - drilling machines, cranes, jackhammers and rock drills, earth and coal mining machines.

Local vibration is generated by instruments such as:

- rotary (grinders and polishers, chainsaws);

- rotational impact wrenches;

- percussive (chipping hammers, riveters);

- impact rotary (mining mechanized tools, punchers);

- pressing (scissors with more than 500 strokes per minute).

Metal chippers, riveters, fellers, grinders and other workers are exposed to this vibration.

Reasons

The cause of vibrations are unbalanced force effects - reciprocating or rotational; impact interactions in gears, rolling bearings, engine and compressor valves, crank mechanisms. Mechanical vibrations can also occur in robotic plants and lines.

As design and technology factors,vibration-causing industrial premises, the following can be distinguished:

- incorrect arrangement of bases and equipment foundations;

- excessive rigidity of structures (fastening of working platforms, seats, controls and other elements);

- design features of equipment;

- technological errors in the manufacture of components (imbalance of rotating flywheels, shafts, errors in the manufacture of parts);

- poor installation of equipment on site;

- increased load or speed during operation;

- Untimely scheduled preventive maintenance of equipment.

Effect on the human body

The impact of industrial vibration on human he alth is complex:

- bone and articular disorders - dystrophic lesions of the spine (osteochondrosis, spondylosis), decreased bone density (osteoporosis);

- deterioration of cellular and humoral immunity;

- cardiovascular diseases (angiospasm - narrowing of blood vessels, impaired blood circulation and tissue nutrition, development of venous stasis);

- microtraumatization of tissues;

- decreased activity of antioxidant defense enzymes;

- neuropathy.

With prolonged local vibration, numbness of the fingers is felt, diseases of the joints and neuroses of the extremities develop. General vibration also affects the vestibular apparatus, gastrointestinal tract, organssenses (decrease in visual acuity and hearing) and other systems. The most harmful vibrations are those whose frequency is in the range of 3-30 Hz, since their values are close to natural vibrations of human organs (there is a resonance phenomenon). Vibrations with a frequency of 6-9 Hz can cause rupture of internal organs.

The severity of the influence of mechanical vibrations depends on the following factors:

- spectral composition;

- direction;

- impact site;

- duration.

Vibration sickness

The systematic influence of industrial vibration contributes to the emergence of vibration disease. It is curable only in the early stages. Subsequently, if irreversible changes occur in the internal organs, it is impossible to get rid of it.

As subjective signs, this pathology manifests itself in the form of the following symptoms:

- dizziness, headaches, flashing "flies" in the eyes;

- bursting pain in the arms, worse at night;

- numbness, chilliness, whiteness, swelling of the fingers; burning, tingling in them;

- bad dream;

- feeling worse;

- decrease in performance.

Other signs are also characteristic:

- hypotension;

- multiple organ failure caused by insufficient blood supply (at the stage of decompensation);

- decreased heart rate;

- metabolic disorders (hypothyroidism and other pathologies);

- decreasesensitivity;

- angiodystonia;

- pathologies of the musculoskeletal system (myofibrosis, arthrosis) and others.

Rationing

Rationing of industrial vibration is carried out in order to exclude the possibility of vibration disease in workers and employees. Controlled parameters are regulated by GOST 12.1.012-90, which contains tables with restrictive values of the main indicators.

Sanitary norms of industrial vibration of general and local type are normalized depending on the geometric mean values of the oscillation frequency. There are several classes of danger in which the occurrence of vibration disease is possible. The first corresponds to the most minimal level (optimal working conditions), at which there is no contact with general and local vibration.

Sanitary and hygienic measures to prevent negative consequences from mechanical vibrations include certification of workplaces, preliminary and current sanitary supervision, control over the use of personal protective equipment (vibration dampening gloves, shoes).

Methods

There are several methods for assessing industrial vibration:

- frequency - the vibration spectrum is measured (the RMS values of vibration velocity and acceleration are calculated in full frequency bands or 1/3 of the range);

- total (integral) estimate by frequency (adjusted value of vibration velocity and acceleration or their logarithmic indicators);

integral, taking into account the duration of the effect of vibration by the equivalent value

Weight factors are chosen according to the recommendations of CH 2.2.4/2.1.8.566-96.

Instruments

Measurement of mechanical vibrations under working conditions is carried out using the following instruments:

- vibrometers (IShV-1, Assistant, VShV-003, models from Brüel & Kjær and others);

- weight and bandpass filters;

- vibration sensors (DN series manufactured by Vibropribor, Brüel & Kjær and others);

- sound level meters (to detect equivalent levels in common frequency bands);

- level recorders;

- magnetographs for recording vibrations in order to conduct frequency analysis, calculate the equivalent level.

Measurement points are selected on surfaces in contact with the human body. If the workplace is not permanent, then the control is carried out at least at 3 points with maximum vibration. To measure the overall vibration, instruments with a higher sensitivity are chosen. Vibration sensors are installed in three mutually perpendicular planes.

Recommended:

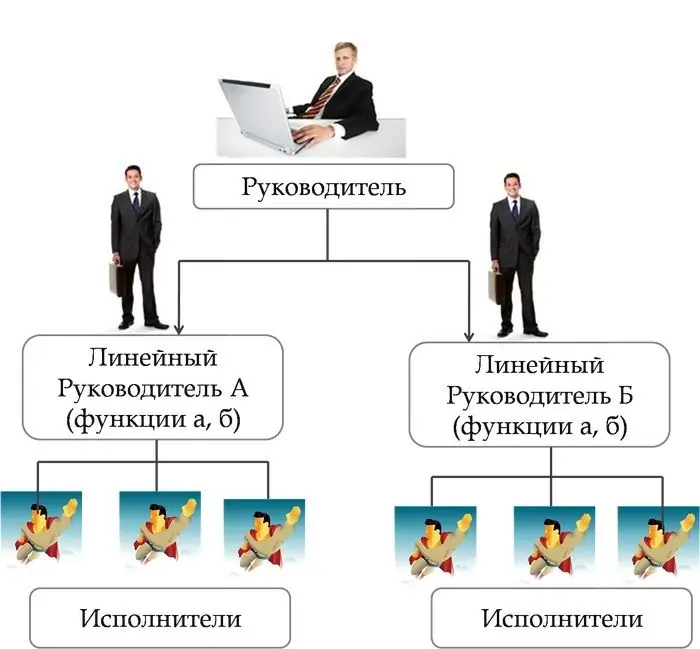

Horizontal links: concept, management structure, types of links and interaction

Horizontal connections in the management structure: general concept, varieties (functional, linear, linear-functional divisional) and their description. The main characteristics of connections and forms of their manifestation. Conditions necessary for the effective functioning of groups built according to the type of horizontal links

Types of packages. Packaging of goods, its functions, types and characteristics

Each of us knows what packaging is. But not everyone understands that it serves not only to give a presentation to the product and make it more comfortable to transport. Some types of packaging are needed solely to protect the product from mechanical damage. Others - to give an attractive appearance, etc. Let's look into this issue and consider not only the main types, but also the functions of the packages

Tax and tax payments - what is it? Classification, types, concept and types

Currently, the tax system is a set of taxes and fees established by the current legislation of the Russian Federation, which are levied in the budgets of different levels. This system is based on the principles provided by law. Let us consider in more detail the issues of essence, classification, functions and calculation of tax payments

Main types and types of business plans, their classification, structure and application in practice

Each business plan is unique, because it is developed for certain specific conditions. But you need to familiarize yourself with the features of various types of business plans in order to understand their key features. Experts recommend doing this before compiling your own similar document

The main classification of steels and its types

An alloy of iron and carbon with a content of the latter of not more than 2.14% is called steel. The main qualities of steel: strength, ductility, toughness, elasticity, wear resistance and others