2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:31

Despite its apparent simplicity, the water valve is a relatively complex design, the build quality and reliability of which directly affect the workflow when supplying water. In this regard, all fittings, valves and other elements must comply with certain standards, ensure the performance of the required tasks. Consider the features of these parts and their characteristics.

Varieties

Plumbing valves can be parallel or wedge type. In the first case, the sealing part of the shutter is placed in parallel, without forming any angle. Such modifications are divided into single and double disc variations.

The wedge locking device ensures passages are blocked by shifting the gates perpendicular to the moving flows. Such modifications are used in the maintenance of pipelines with water, steam, gases, and some oil products. The wedges can be one-piece rigid, elastic or in the form of twin disks coated with high-alloy steel. The design facilitates the replacement of glands during system construction or maintenance.

Spindles

Depending on the type of water valve, it is equipped with a block with different direction of movement of the spindles. There are two types of configurations in this plan:

- Retractable spindle. In this case, the opening and closing of the valves is carried out using translational or helical movements. Such elements, as a rule, have impressive dimensions.

- Non-retractable rotating analogue. This element is smaller in height, it is usually used in the transportation of water, oil products and other liquids that do not cause corrosive processes. The remaining flows are transported through rising stem valves.

The locking device in the design is a steel partition with various parameters, which is in demand when shutting off gas and liquid in the event of a pressure drop.

Working principle

The water valve is designed to turn on or off the flow of the medium used. Temperature exposure - up to 225 degrees Celsius. The cast iron element on horizontal pipelines is mounted upwards with flywheels with vertical spindles.

On a vertical structure, the valve is installed flat, and the spindles look to the horizon. All types of considered locking devices belong to repaired types of products. All configurations are available for manual or automatic operation (via electric drive).

The second modification is more convenient and practical, thanks to morewide functionality. Using the buttons, you can stop the water valves in any intermediate positions. In addition, automatic deactivation of the motors occurs when the locking mechanisms reach the extreme points. An optional shutter position sensor allows you to see if the passage is open or closed.

Features

Among the advantages and features of the mechanism under consideration, the following points can be noted:

- When using this part, the flow of the transported flow is performed in any direction.

- The element has a small construction length.

- The ability to block liquid and viscous flows with little hydraulic resistance is observed.

- Withstand pressure up to 25 MPa.

- Possible fluctuations in diameter (DN) - 50-1200.

- Temperature limit - up to 450 degrees.

- Not only water can act as a working medium, but also oil, acids, alkali, oil products.

Cast iron water valve

Such a locking device is widespread and used in pipelines with nominal diameters of passages from 50 millimeters to 3 meters. The modification is distinguished by its simple design and the presence of a small hydraulic resistance. The last parameter is due to a handwheel with a manual drive, providing a shift of the shutters up to the absolute overlap of the gaps.

Depending on the design features, the device of water valves can be full bore orconstricted. The first option is characterized by lower hydraulic resistance, as well as the presence of a larger diameter. Reduced versions are mainly used in systems where the working fluid moves at set speeds.

The distinguishing element of the cast iron locking elements is the retractable spindle, which facilitates maintenance due to convenient access to the structural components.

The non-rising stem configuration also has its advantages. The main one is its compact size, which allows you to place the part in small compartments (1.5 times smaller than the previous element).

Steel counterparts

Water flanged valves made of steel are operated in open/closed modes. They are used as control valves in the presence of an open-type hydraulic system with a nominal pressure of up to one atmosphere.

The products in question are classified according to the following parameters:

- Drive type.

- Placing moving nodes.

- Method of connecting to the pipeline.

- Types of shutters.

Steel wedge gate valve, in turn, is divided into rigid and composite modifications. In the first variant, one-piece cast wedges are provided, providing good tightness. Their disadvantage is that when significant temperature fluctuations occur, the elements are prone to jamming. To avoid this, a gate valve with a double-disk locking mechanism was created.

Connection withpipeline

Fixation of water valves, the diameter of which corresponds to the pipeline, is carried out using flanges and bolts or by welding. The second method is considered stronger and more reliable; it is used for processing structures with aggressive liquids. At the same time, there is no leakage and excellent tightness. Despite their small dimensions, the installation of valves requires care and precision.

According to the manufacturing method, the shutoff valves in question are divided into the following categories:

- One-piece modifications.

- Welded options.

- Stamped analogues.

Cast gate valves are the most common because they are the most reliable. Their advantages include ease of operation, low hydraulic resistance and short length. Among the minuses - a long period of opening and closing, as well as the presence of high altitude. With their help, it will not be possible to adjust the flow rate of the working fluid.

Installation recommendations

Regardless of the types of water valves, they have similar rules that must be observed during installation. It is necessary to choose a system taking into account the characteristics of operation. For example, if shut-off elements are installed in pipelines with a gradual decrease in work flows, the body parts of the parts experience high-frequency vibrations with incomplete gates. This provokes intensive wear of products, up to failure. As a result, you will have to disassemble the entire structure, perform a complete replacement andlapping of elements of stop valves.

The following factors influence the duration of the working resource:

- Proper installation.

- Preparation of working planes and operating environment.

Before installing the valves, it is recommended to steam the surfaces with hot water, after which they must be dried. Beforehand, the pipeline itself should also be cleaned of foreign particles and dirt. Mounted elements must comply with the parameters of the technical passport. Otherwise, the product will quickly become unusable.

Helpful tips

Do not install valves with the handwheel down. This causes fluid to leak or gas to evaporate.

When flanged, it is necessary to ensure that all aggregating elements are aligned with each other without distortions.

Before the installation of valves, pipes and other elements to be mounted must be thoroughly cleaned of rust, oil, dirt, and foreign particles. Only such an approach can guarantee high quality installation and a long working life.

Finally

It is worth noting that the price of water valves depends on the size and material of manufacture, as well as on the configuration. The average cost of such a locking mechanism is from 5 to 60 thousand rubles. Regardless of the types of elements under consideration, they play an important role in the design of pipelines for various purposes. The main thing is to take into account when choosingfeatures of operation, working fluid and installation features.

Recommended:

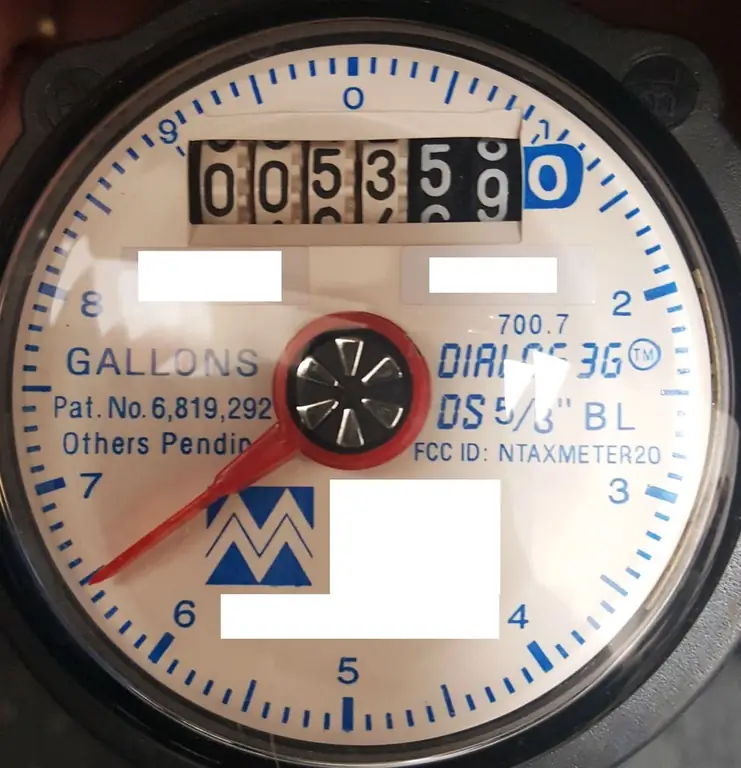

Shelf life of water meters: period of service and operation, verification periods, operating rules and time of use of hot and cold water meters

The shelf life of water meters varies. It depends on its quality, the condition of the pipes, the connection to cold or hot water, the manufacturer. On average, manufacturers claim about 8-10 years of operation of devices. In this case, the owner is obliged to carry out their verification within the time limits established by law. We will tell you more about this and some other points in the article

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

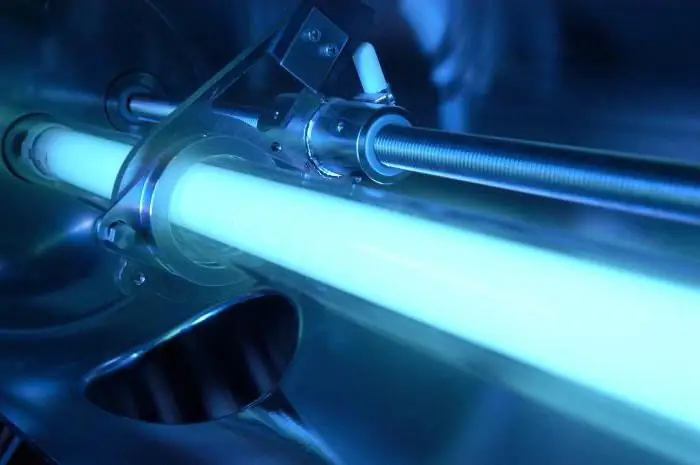

UV water disinfection: principle of operation, installation. Drinking water - GOST valid

Technologies in the field of water treatment do not stand still. Today, many methods are used to ensure the required quality of drinking liquids that meets the requirements of GOST. One of them is ultraviolet disinfection of water. It will be discussed in the article

Water tower: principle of operation, purpose, characteristics

Water tower is the simplest design designed for autonomous regulation of water flow and pressure in the plumbing system. The simple principle of operation of the water tower determined its widespread use

Low pressure heaters: definition, principle of operation, technical characteristics, classification, design, operation features, application in industry

Low pressure heaters (LPH) are currently used quite actively. There are two main types that are produced by different assembly plants. Naturally, they also differ in their performance characteristics