2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:35

Natural fibers (cotton, linen and others) are the main raw material for the domestic textile industry. They are made from various natural products.

Origin of natural fibers

Raw materials, again, are obtained from various products. Depending on the material, the fibers differ from each other in quality, appearance, and other characteristics. At the same time, there is a category of the most commonly used raw materials. In the textile industry, natural plant fibers are in the first place in terms of use. Their characteristics depend on the characteristics of the crops from which the raw materials are made. In addition, natural fibers of animal origin are used. These include, for example, wool, silk.

Properties of natural fibers

As mentioned above, the characteristics of raw materials depend on the characteristics of the products from which they are obtained. The most common are cotton fibers. They are obtained from a specially grown crop. Cotton is cultivated in more than 50 countries. It is a perennial thermophilic culture. The plant looks like a shrub, the height of which is from one meter andmore. Every year, after flowering, fruits are formed on the culture. They are presented in the form of boxes with seeds. They are covered by 7 to 15 thousand hairs. They are cotton fibres. The length of the hairs is in the range of 12-60 mm. The longer they are, the better the yarn and fabrics. Textiles are produced from natural fibers, which can be easily dyed and processed. As a rule, the feedstock for industry has a white or brown color. Meanwhile, at present, cultivation technologies can produce colored natural fibers.

Bat raw materials

Natural fibers are obtained from the stems and leaves of various crops. These, for example, include jute, flax, nettle and others. Linen natural fibers are considered the thinnest, most flexible and softest. From them, yarn is first created. Strong and soft fabrics are subsequently produced from it. Linen is of several types. The length of the fibers depends on the height of the stem. The most valuable in the industrial sense is fiber flax. Its stems can reach a height of 0.8-1 m.

Process of obtaining raw materials

Ripe flax stems are pulled out along with the roots. This is necessary to maintain the length of the fibers. This process is called "pulling". Previously, it was done manually. Currently, special combines are working in the fields. On flax threshers, the stalks are freed from seeds. The resulting straw is soaked in special pools or other bodies of water. Part of the flax stem is the bast. It is located under the bark. In the form of thin ligaments, it contains fibers. Their isolation from the stems is carried out at special plants. The enterprises use a special technology for separating the fibers from the bark and their subsequent processing. The soaked stems are dried. Then they are crushed and shaken. The natural fibers are then bleached as they have a light yellow to steel color.

Other crops

The fibers of other plants are coarse and tough. They are mainly used in the manufacture of ropes, canvas, burlap, ropes, etc. For example, hemp fiber is a natural material and is similar to linen in many ways. However, it is not as soft. In this regard, it is used, as a rule, in the production of canvas, burlap, twine, ropes. Bast natural fibers are obtained not only from the stems. Leaves can also serve as a raw material, for example.

Silk

For its production, fibers are used, which are obtained from silkworm cocoons. They are formed at a certain stage of caterpillar development. They weave a cocoon, which is an oblong egg-shaped shell. It consists of the finest fiber, which is interwoven in 40-50 layers. The thread is formed as follows. There are two holes on the head just below the caterpillar's mouth. A thick liquid is released from them, which freezes in the air. Her education is ongoing. As a result, 2 strands are formed, which are glued together with sericin. This is a special substancewhich is also distinguished by the caterpillar. As a result, one thread is created, which goes to weave a cocoon.

Industrial processing

The color of the cocoon depends on the type of silkworm. They are reddish-yellow, white, yellowish. Other types of silkworms are also bred, which weave pale pink, green, blue cocoons. However, it should be said that the natural color of the threads is not stable. In addition, colored fibers can subsequently complicate the dyeing process. Cocoons are bleached before further use in industry.

To obtain high quality fibers, cocoons are treated with steam or hot air. The pupae in them are killed, and to prevent decomposition, they are dried. If this is not done, then the insect will turn into a butterfly and begin to get out of the cocoon. Accordingly, it will be subjected to mechanical damage, which negatively affects the quality of the threads. Before starting to wind the fibers, the cocoons are placed in pools filled with hot water. Then they are treated with steam and alkaline solutions. This is necessary to soften the sericin. One cocoon gives about 400-1200 m of thread. However, it is very thin. Therefore, fibers from 3 to 30 cocoons are combined into one.

Wool

What other natural fibers are used in industry? Animals give industry and wool. It is also processed to obtain threads. Wool has a variety of qualities and characteristics. Differences are present infibers of one animal of different species. For example, from sheep's wool, the one that is obtained from fine-fleeced and semi-fine-fleeced sheep is of great value. In the process of cutting, the hairline is removed in a continuous layer. Fleece varies in quality. The most valuable fibers are located on the back, abdomen, shoulder blades. The hair on the legs and back is coarse. However, down is considered the highest quality and most valuable. Its fibers are flexible, elastic and thin. The quality of wool largely depends on the time of cutting. The fibers obtained in the spring will be softer. They have a lot of fluff. In autumn it is almost absent in wool. Therefore, these fibers are rigid. However, the autumn wool is cleaner than the spring one. Among the fibers are distinguished:

- The awn is a thick fiber.

- Transition hair. According to its characteristics, it occupies an intermediate position between the awn and down.

- "Dead" hair. It is presented in the form of rigid and low-strength fibers.

Processing Features

The properties of the yarn will depend on the quality of the fibers that were used to obtain it. The best varieties are made from fluff. The quality of fibers is determined not only by their strength, softness, fineness, but also by their length. She, in turn, will depend on the breed of sheep. The length of wool can reach 180-200 mm. Raw materials are always subjected to primary processing. It includes sorting, cleaning of garbage (lumps of earth, burdock, etc.). Then detachment, loosening is performed. After that, the wool is washed and dried. Sorting is done manually. Fleece is laid out on special tables. Here it is divided into parts. In accordance with certain quality standards, the wool in the batch is selected. Washing is carried out with special compositions with the addition of detergents. This is necessary to remove fat particles.

Chemical raw materials

With the development of technology, it became possible to produce artificial and synthetic fibers. The high demand for textiles is cited as the main reason for the use of chemicals in the production of raw materials. The available resources of natural material could not meet the needs of the population. Obtaining artificial raw materials is carried out using natural polymers. These, in particular, include cotton, wood and other cellulose, milk proteins, etc. These substances are subjected to chemical treatment with nitric, sulfuric, acetic acids, acetone, caustic soda, and so on. The result is viscose, nitro silk, acetate, copper-ammonia silk.

Synthetic raw materials

They are obtained by processing different products. Among them: oil and coal, associated and natural gases, agricultural waste and pulp and paper production. High molecular weight resins are isolated from substances. They act as the starting material for the production of synthetic raw materials. Processing and processing of resins is carried out according to a special, rather complex technology. Among synthetic fibers, nylon, lavsan, kapron, milan, polyvinyl chloride and others are most widely used. Chemicalraw materials are given certain qualitative characteristics in advance. In particular, it is durable, resistant to moisture, paint, etc.

Mixed raw materials

The chemical and natural fibers mentioned above are homogeneous materials. Meanwhile, today the mixing of raw materials is gaining more and more popularity. The introduction of new technologies in textile production provides ample opportunities for obtaining a huge range of yarn. Natural fibers can be mixed both with each other and with artificial and synthetic materials. For example, they combine nylon and linen, nylon and wool. To obtain semi-silk and semi-woolen fabrics, not only a mixture of fibers is used. New technologies of weaving are actively applied. In particular, when creating a linen, the warp threads are the yarn of some fibers, and the weft - of others.

Conclusion

The textile industry is considered one of the largest manufacturing sectors. High-quality raw materials must be used to manufacture demanded products. It must comply with state standards, be subjected to careful processing. This is important for fibers of any origin, including chemical ones. It should be noted that advanced production technologies are constantly being introduced in the industry. This, in turn, requires the supply of new raw materials.

Recommended:

Compressed natural gas is Definition, composition, properties

Compressed natural gas is one of the most economical types of fuel today. Engines of both passenger cars and public or freight transport can work on CNG. A feature of such fuel, among other things, is considered to be a lower degree of fire hazard than that of gasoline or diesel fuel

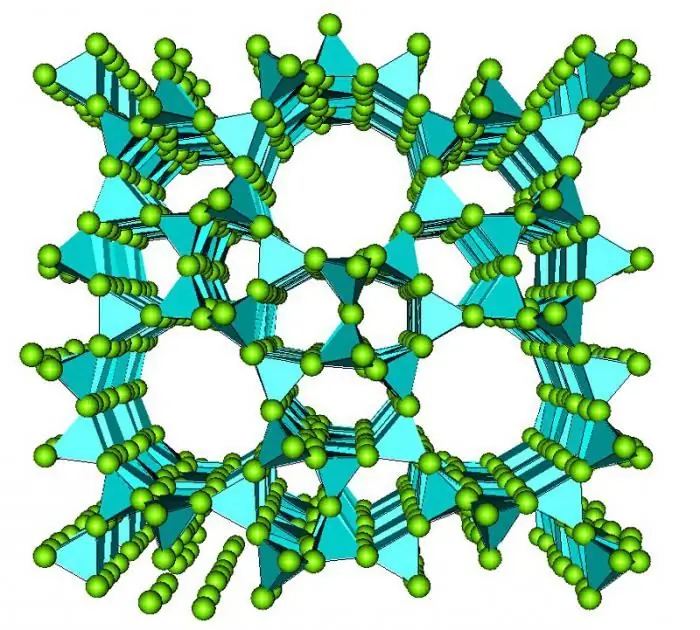

Zeolite - what is it? Zeolite natural and synthetic. Zeolite: properties, applications, benefits and harms

Its name translates as "boiling stone". It is impossible to count the uses of this seemingly simple mineral. It can even be eaten and used as a sieve for molecules. Such a versatile and useful zeolite

The use of natural gas. Natural gas: composition, properties

What do we know about hydrocarbons? Well, perhaps something from the school curriculum in chemistry, and the word methane periodically flashing in the media … What do we know about natural gas, except for its explosive properties? What other use of natural gas, besides the well-known cooking and heating of residential buildings? What's new in the world of energy consumption and energy security?

Coal: properties. Hard coal: origin, production, price

Since ancient times, mankind has been using coal as one of the sources of energy. And today this mineral is used quite widely

Polypropylene fibers: composition, properties, application

Polypropylene fiber has found wide application in modern industry. This inexpensive material with excellent performance is used to make car brushes for cleaning roads, furniture upholstery, fillers, etc