2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-06-01 07:12:56

Quality management, development of a quality manual - today these are the most important tasks in the quality management system of products or services provided. It is advisable to analyze this issue in more detail, consider all its aspects separately.

Choosing an approach to document development

One way or another, the development of an organization's quality manual is preceded by the choice of a specific approach. In other words, you need to figure out which points are worth describing in the document, and which are not. Employees of any company should use this "reference book" in their professional activities, so this factor must be taken into account when creating it. How to organize the development of a quality management manual so that it is effective and efficient?

In order for any document to be effective, it must be understood that it must be both understandable and comprehensive. He mustbe convenient to use. That is why, in the process of developing a quality manual, it is important to take into account that it, as a rule, includes all the basic information about the structure's quality management system. If necessary, links to additional documentation become relevant. Simplicity of presentation and clarity make it possible to use the manual both for specialists working in the field of quality and for other employees of the company. The ease of use, which is so important to consider in the development of a quality manual, ensures that employees will refer to this document more often, and not look for solutions through colleagues or on their own.

Completeness as a basic requirement for guideline development

Recommendations for the development of a quality manual for a laboratory, manufacturing plant or other company include the completeness of the material presented. It would seem that this requirement is one of the most difficult. But you should not be afraid. Fortunately, in our case, a thorny path has already been passed, because at present there are ISO quality management standards. They are a clear regulation of what elements the quality management system of an enterprise should consist of. In addition, the standards allow you not to wonder how this system is created and how it should work.

When developing a quality management manual, you need to know that the key section of the document is the description of the goals of the structure inthe field of quality. In other words, we are talking about ideas that the company plans to implement in a specific period of time. The achievement of the goals named by the developer is due to the competent fulfillment of the requirements in the field of quality. So, when developing a quality manual for an enterprise, it is worth highlighting how each of these requirements is implemented separately in this structure. Typically, the titles of the requirements are the headings of the sections of the document in question. It should be added that in the process of preparing the manual, one should not give free rein to one's own imagination regarding the numbering of sections. When developing a quality manual, it makes no sense to deviate from the numbering that is approved in the standard. Only then will the final document be understandable and recognizable both among the company's employees and external auditors.

It is important to keep in mind that certain people are usually responsible for meeting the requirements of the standard in the enterprise. Accordingly, these officials must be indicated when developing the quality manual, namely after the description of individual requirements. Both the owners of the processes and specific officials who manage the activities described in the documentation can be responsible.

Clarity as a requirement for guideline development

When developing a quality manual for a laboratory, manufacturing plant or other structure, it is important to consider a number of requirements. In addition to the completeness of the presentation, a significant role is played byunderstanding of the material. One way or another, management should create an idea of the processes taking place in the company and their interaction. This is done for the sake of meeting the requirements of the standard.

So, if there is a specific process, the implementation of which fulfills a certain requirement of the standard, it is necessary to indicate in the document not only the process itself, but also its owner. If the requirement is met for an activity that is not characterized as a process, a documented procedure should be specified with instructions for the implementation of this activity with appropriate comments that are causal.

When forming a quality manual for new requirements, it should be taken into account that, as a rule, additional documentation is needed to fulfill these requirements. These are, for example, process regulations that specify the composition of those responsible and the stages of the processes themselves. It is important to know that references to these documents are necessarily fixed in the manual. As a result of the implementation of these operations, any employee should understand from the first reading what is expected of him in terms of implementing the requirements of the quality standard and the corresponding goals in this area. The employee must keep in mind what are the ways to achieve these goals, at least at his workplace. The implementation of these recommendations on the development of a quality manual will make it possible to involve all employees of the organization in the process of managing the quality parameters of products or services provided.

Ease of usemanuals

Another important requirement for the development of a quality manual for a laboratory, manufacturing enterprise or other structure is its ease of use. It is impossible to argue with the fact that even on the most powerful car you cannot go far, and indeed you cannot leave at all if its steering wheel is installed in the trunk. And overloading the instrument panel with all sorts of secondary sensors will somehow lead to the fact that the driver will begin to be distracted from the main process in his case in order to read interesting indicators.

Example of an ISO quality manual

It would be useful to review the manual and its standard sections with a specific example. To do this, we will take a testing laboratory. The first section of the document is an introduction. It reads:

- name of the structure in full and abbreviated form;

- regulation of the activities of the laboratory, where it is necessary to indicate the names of papers and their registration numbers;

- location of the legal entity, where you need to specify both postal and legal address;

- contact details (email, phone number);

- organizational structure of the company, which, as a rule, can be found in the appendices to the main document.

By the way, it is best to display the organizational structure schematically.

Scope of application

After the introduction during the development of the quality manualit is important for the testing laboratory to indicate the scope. This topic is taken out in a separate section, usually the first in a row. For example:

- This document presents the quality management policy and the key principles and practices that ensure the functioning of a quality system in a research laboratory.

- The manual is developed by one or another employee, signed by the director of the research center, and also approved by the organization's management and secured through the seal of the legal entity.

- In order to ensure that the quality system is maintained at a high level and effective, and corrective actions are taken in a timely manner, the manual is reviewed and supplemented if a legal entity is changed or reorganized, as well as in the event of a change in the scope of accreditation of the structure or improvement of the quality system.

- This document has been compiled to comply with the requirements of certain country laws and regulations.

- The scope of the quality management system extends to all points of implementation of laboratory activities.

Normative references

The second section of the document in question usually contains normative references. It is important to note that all laws, regulations, reference books and other sources that are used in the preparation of the quality manual must be clearly and in detail described and marked. Further, it is advisable to proceed to the acquaintance with the third section of the manual, which describes all the terms and definitions,used in the work.

Terms and definitions

This section is quite large, so let's consider it on a specific example of our laboratory. The following terms and definitions apply in this document:

- Accreditation is a confirmation of the compliance of a legal entity or individual entrepreneur with certain criteria.

- An extract from the register (in other words, an accreditation certificate) is a document that is generated automatically using the means of the state information system in the field of accreditation. It is a certificate, confirmation of the fact of accreditation in a specific field of activity.

- Quality is a set of properties inherent in an object. Typically, these characteristics refer to the facility's ability to meet the needs that were originally established.

- QCA, or Quantitative Chemical Analysis, is a quantitative determination formed experimentally and referring to the content of one or more constituents of a sample by physical or chemical means.

- An analysis technique is a complex of specifically characterized operations, the implementation of which leads to obtaining CCI results with established accuracy indicators.

- Audit, or internal review, is a documented, independent, systematic process of obtaining audit results and objectively evaluating those outcomes in order to establish the extent to which previously agreed audit criteria have been met.

- The audit program isa set of established criteria for the audit of one or a series of audits that are planned for a certain time period and are aimed mainly at achieving the set goals.

- Audit criteria is a set of requirements, procedures and policies that are used as references. It is important to note that audit criteria are used to match audit evidence against them.

- An auditor is a person who demonstrates his or her personal characteristics and competence to carry out an audit.

- Audit team - one or more auditors who are involved in the audit.

The list of terms and definitions can be continued, but the main purpose of this article is to clarify the meaning and nature of the material published in each section of the guide, so it is advisable to move on to the next paragraph.

Laboratory quality management requirements

This paragraph is the final one in the document under consideration. However, it is the most informative. To begin with, it is necessary to indicate the name of the laboratory here, as in the first section, and then provide information about the management of the structure, namely, you need to describe the position of the head of the research center or quality manager and to whom they report. After that, it is advisable to characterize the organizational structure and management personnel with positions and related professional responsibilities. In addition, it is important to remembersubstitution paths, that is, deputy directors of different departments of the laboratory. Next, talk about:

- Responsible for the quality management system employee. It is necessary to indicate not only his position, but also the data of the corresponding order for employment.

- Implementation of the QMS and the basics of its functioning.

- Responsibilities and powers of the employees of the research center in the field of quality, including the distribution of duties, rights and responsibilities between the employees of the research center.

- Regulations of the activities of the structure.

- Right Research Center.

- Privacy Policy, even from third parties.

- Responsibility of management for the activities that are organized in the laboratory.

- A set of regulatory and technical documentation, which in any case acts as the property of the customer. So, after laboratory work, this documentation remains in the research center or is returned to the customer by prior agreement.

- The results of the work performed and the issued papers, which act as the property of the customer only after the work has been paid.

What else?

In addition to the items above, in the "Requirements" section regarding the laboratory center, you must specify the following:

- Conclusion of subcontracts for the implementation of measurements. It should be added that the purpose of this procedure is to ensure quality test results inin the case of subcontracting structures being involved in their implementation. In one way or another, the research laboratory is fully responsible for the work that is performed by the subcontracting organization.

- Managing work related to tests that do not meet approved requirements.

After describing all sections of the manual using the example of a research center and a detailed analysis of all the requirements for the document today, it is advisable to draw some conclusions.

The main point is the need to document the entire range of processes carried out in the field of ensuring and improving the quality of products or services provided. It is also important to have a document regulating the issues of document management in general as part of documented processes.

Recommended:

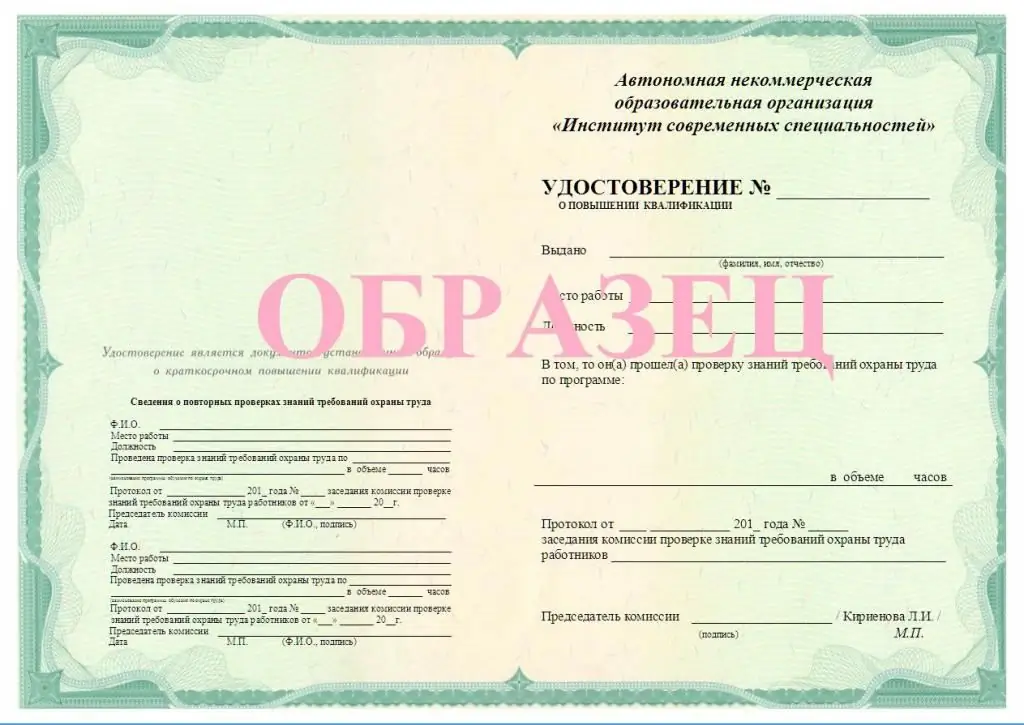

Professional development in labor protection: features, requirements and recommendations

There is a labor protection engineer in every production. This person is obliged to create comfortable working conditions, as well as to check compliance with safety regulations. And this means that qualifications need to be constantly upgraded

Rules of land use and development of the municipality: features and procedure

The Municipality Land Use and Development Regulations is a zoning document. It is adopted by the authorized regional authority after public hearings

Real estate development and its role in economic development. The concept, types, principles and foundations of development

In the framework of this article, we will consider the organization of the real estate development system and its role in economic development. The basic concepts, types and principles of organization of the development system are considered. The characteristic features of the system in Russian conditions are considered

"Quality Circles" is a quality management model. Japanese "Quality Circles" and the possibilities of their application in Russia

Modern market economy requires companies to constantly improve their technological processes and staff training. Quality circles are a great way to involve active employees in the workflow and implement the most productive ideas in the enterprise

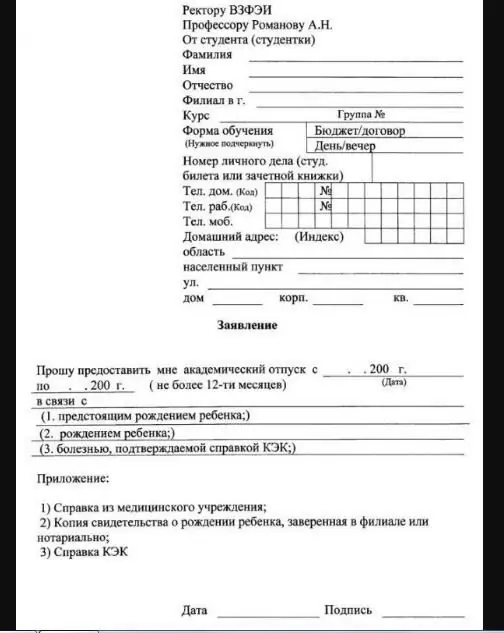

Academic leave at work: the procedure for registration, conditions and requirements, help and advice from lawyers

You can't take academic leave from work. However, usually, when looking for an answer to this question, they actually mean not academic, but student leave. It's just a change in concept. In the article, we will understand what is the difference between them, and why confusion occurs