2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:39

Transformer substations are an integral part of modern energy supply infrastructure. They are used at the stage of power distribution, allowing to minimize the processes of distortion of current characteristics during its transmission over long distances. There are different types of such objects, which differ in the features of the design, approach to installation and operation. In turn, the mast transformer substation is the most common structure of this type, providing a number of advantages.

General information about mast substation

Mast, or pole, substation is made as a single transformer unit, which, depending on the characteristics, can operate with a power range of 25-250 kVA. During operation, such installations can, on average, receive AC electricity with a voltage rating of about 6 kV. With a quality installation, a pole transformer substation is able to maintain optimal performance both in frost conditions and at high temperatures in summer.

Great dangerrepresent threats related to the direct function of such objects. Depending on the operating conditions, there may be risks of short circuits, line overloads, phase-to-phase failures and overvoltages. For this reason, already in the basic configuration, the mast transformer substation is supplied with a wide range of protective systems. In addition, electrical and mechanical interlocks are provided to ensure the safety of service personnel.

Designation of mast substation

The function of a transformer substation is related to the need to reduce losses in power lines. This task can be achieved in different ways, but in this case, the installation must provide an increase in the voltage in the network. For this, the substation is provided with an electrical installation that performs the function of converting and distributing energy. The workflow involves several components, including switchgears, control systems and auxiliary mechanisms that provide the tasks of supporting the operation of the structure itself. Again, depending on the application and operating conditions, the distribution of electrical energy by a mast substation can occur with different characteristics of the power system. Also, some models provide for the implementation of the task of accounting for electricity. It is achieved using pre-installed counters that can work both on the principle of electrochemical reactions and due to mechanical action.

Operation principle

The source of energy supplied by the substation is full-fledged electricity generation facilities. From them, voltage is supplied to the converting and distributing substation, which is most often located nearby. The aforementioned function of increasing the voltage in order to minimize losses in the line is carried out due to the action of step-up transformer devices. In the future, a step-down transformer can also act as a receiver of electricity, which optimizes the voltage characteristics to the optimal ones from the point of view of use in the local network. To perform these tasks stably, the mast transformer substation must be regularly cooled down. Typically, cooling systems are devices with oil supply mechanisms. This is one of the systems that increase the reliability of this type of substations.

Types of mast substations

There are two approaches to the implementation of the structural design of such substations. A simpler option is a complete transformer substation, which has an A-shaped external design. Such structures include a set of disconnectors with drive mechanisms, discharge elements, fuses and a power transformer unit with a distribution module.

The second option is a more complicated, more functional and productive U-shaped station. And if the first variety is most often complete, then in this case, installation can be carried out using ready-to-useblock installation. However, a complete transformer substation is often used in this configuration. The structure of this system includes the same set of components, but with some differences. In particular, the U-shaped station also has voltage limiters, and the distribution module is usually represented by low voltage devices

How is a pole transformer substation installed?

Installation activities include several operations, including the delivery of equipment, assembly operations and fastening of supporting elements. Next, the installation position is reconciled, after which the prepared blocks are filled with electrical equipment. Direct connection of devices to each other is made only after the final revision and adjustment of the devices. Typically, a mast transformer substation is equipped with special equipment. For example, a power transformer can be lifted onto a support by a truck crane. Then the block is fixed - on reinforced concrete supports, fixation is carried out using a metal frame, which, in turn, is held on the support with metal clamps.

Conclusion

Pillar substations due to their design are widely used in various industries. Enterprises produce special models for use in agriculture, improve the basic series of universal use, develop powerful complete structures to serve the needs of industrialobjects, etc. But regardless of the execution, the mast-type transformer substation is also confidently developing in terms of technology. Manufacturers produce components of a new generation, the work of which is already based on the principles of automation. On the one hand, this transition complicates structures and their management, but on the other hand, it allows optimizing energy costs and financial costs for maintenance, not to mention increasing reliability and safety.

Recommended:

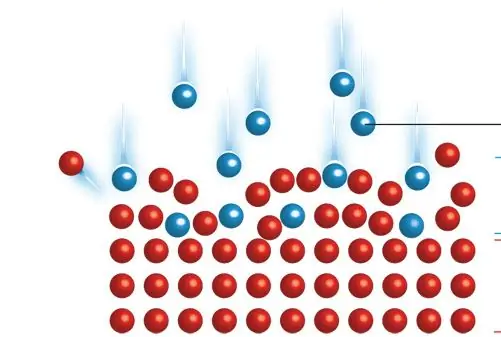

Ion implantation: concept, principle of operation, methods, purpose and application

Ion implantation is a low-temperature process by which the components of a single element are accelerated into the solid surface of a wafer, thereby changing its physical, chemical or electrical properties. This method is used in the production of semiconductor devices and in metal finishing, as well as in materials science research

What is a transformer used for: features, principle of operation and application

To begin with, let's figure out what a transformer is for and what it is. This is an electrical machine designed to change the voltage. They are different depending on the destination. There are current transformers, voltage transformers, matching transformers, welding transformers, power transformers, measuring transformers. Everyone has different tasks, but they are unequivocally united by the principle of action. All transformers run on alternating current. There are no such DC devices

Electric locomotive 2ES6: history of creation, description with photo, main characteristics, principle of operation, features of operation and repair

Today, communication between different cities, passenger transportation, delivery of goods is carried out in a variety of ways. One of these ways was the railroad. Electric locomotive 2ES6 is one of the types of transport that is currently actively used

Complete transformer substation KTP: production, installation

The assembly of equipment such as a KTP substation is carried out in several stages. The case is pre-assembled, then the bus system and communication equipment are mounted. The PTS installation is usually made by the same company that was engaged in its manufacture

Gas piston power plant: the principle of operation. Operation and maintenance of gas piston power plants

Gas piston power plant is used as a main or backup source of energy. The device requires access to any type of combustible gas to operate. Many GPES models can additionally generate heat for heating and cold for ventilation systems, warehouses, industrial facilities