2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:43

To insulate houses today, stone wool is quite often used. It is good because it is not afraid of fire, it is easy to install, and it is inexpensive. One of its popular types is bas alt insulation. Its properties and specifications depend on its specific purpose.

This material is one of the cleanest in terms of ecology. This insulation acts as one of the types of mineral wool, so it has several names, among them - stone or bas alt wool. It surpasses all other types of mineral wool in terms of strength characteristics and is absolutely safe for nature and humans. Recently, bas alt cylinders have become more and more common, and they will be discussed in the article.

Description

Such cylinders are also called shells and are a heater with different diameters and thicknesses. It is based on high-density bas alt fiber, which is 75 kg/m3. Products may be coated, andalso have undeniable advantages over other heaters. The cylinders are slit for ease of installation and allow for repeated use of this material without compromising performance.

Bas alt cylinders can be coated with fiberglass, aluminum foil, fiberglass and other coating materials that are designed to increase wear resistance. On sale you can find Bas alt-Pipe, which is a ready-made thermal insulation made of bas alt fiber. Products for pipes are intended and are produced in the form of segments and cylinders.

Production Methods

Bas alt cylinders are manufactured in accordance with GOST 23208-83. In the process, modern European equipment and materials are used that meet stringent fire safety and environmental requirements. Such pipes are structures made of a layer of rigidly formed bas alt and a cover layer.

Cylinders can be 1m long and are designed for different pipe diameters. In this case, the thickness of the insulating layer can be any. Among the most well-known production technologies, it is worth highlighting the method of pouring thin fibers with a synthetic binder.

Products can be used for thermal insulation of pipelines, the outer surface of which can be heated up to + 250 ˚С. Production technologies may differ depending on what product should be the output. The first technique involves the use of hydromass, the second -boards of semi-dry and hot pressing, while the 3rd one involves the addition of a bituminous binder.

Recommendations for use

Bas alt cylinders are used for thermal insulation of industrial and domestic pipelines. Since it is based on an environmentally friendly material, it can be used in all types of industries, including food. The premises where the heater will be used can have any purpose. Cylinders are suitable for working in different conditions, it can be indoors or outdoors.

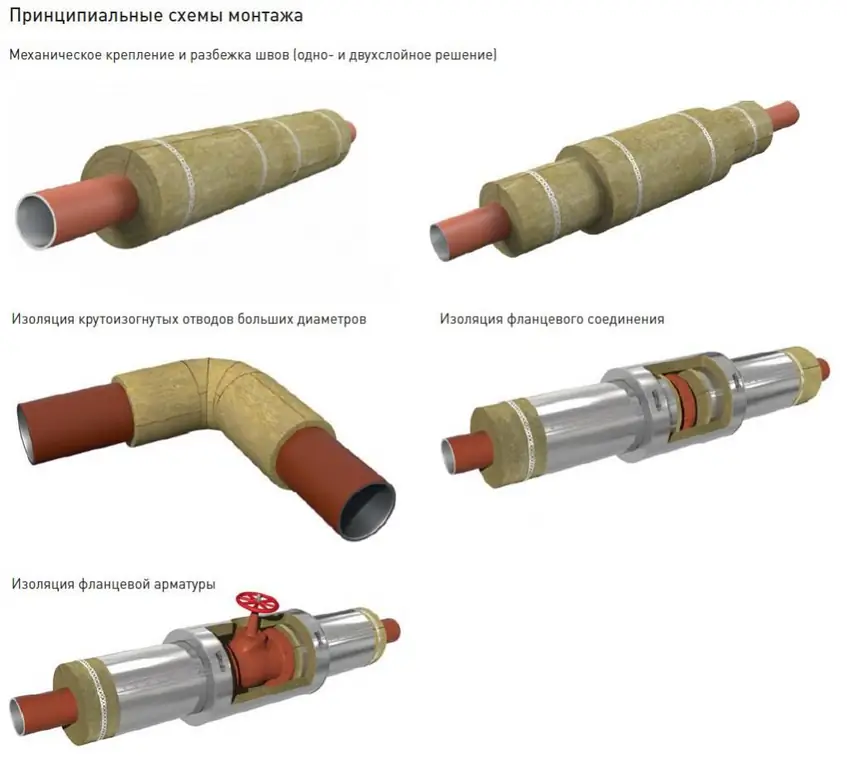

Such shells are used for above-ground and underground laying. Such cylinders are the best way to optimize heat loss in heating systems and heat exchangers. Stone wool cylinders are quite easy to install. To do this, they only need to be opened along the longitudinal seam and put on the pipe. The products have tees and bends, which helps to isolate the most problematic places in pipelines, namely:

- tie-ins;

- transitions;

- knee.

Heat-insulating bas alt cylinders allow you to create a sealed system without joints and seams, which must be closed with aluminum tape during installation. In order to protect the insulation from external factors such as mechanical damage and precipitation, coated cylinders or heat-insulating cylinders, which are produced in galvanized casings, should be used.

Additional Installation Recommendations

One of the key stages on the way to high-quality insulation is the correct execution of installation work. Manipulations should be carried out from the flange connection. Cylinders must be installed close to each other. Horizontal seams should be spaced.

Fastening on the pipeline is carried out with galvanized knitting wire or bandages. Two bandages are installed on one product, the distance between which should be 500 mm. Bandages can be made from packing tape or aluminum bands. Their fastening is carried out by buckles made of thin-sheet galvanized steel. Their thickness should be 0.8 mm. It is acceptable to use rings made of black annealed wire or galvanized steel, while the diameter of the products can reach 2 mm. Stainless steel wire can be used.

Specifications

Cylinders made of mineral bas alt wool have a thermal conductivity of 0.04 W/mK. Synthetic binder can start to melt only at temperatures above 1000 ˚С. The service life of such products exceeds 50 years. They do not shrink and are resistant to chemicals. They have low water absorption, and the temperature regime can reach + 650 ˚С. The lower threshold is - 150 ˚С. Moisture absorption does not exceed 5%. Bas alt pipe cylinders are non-combustible materials.

In closing

After the installation of the cylinders on the pipeline system, the protective shell should be installed. She ismade of galvanized steel. An alternative solution is 0.5 mm aluzinc. The containment is installed from the containment outlet sections. Work must begin from the valves.

Protective sheath must be installed with an overlap. And for the convenience of fastening the casing, you can use a tie-down strap with a ratchet locking mechanism. The outer diameter of the insulated pipelines can reach 915 mm. Of the important stages in the design of engineering structures, the choice of the desired insulating material should be highlighted. The ability to maintain the desired parameters of heat or cold of the carrier depends on this, as well as to comply with the fire safety requirements of the system.

Recommended:

Gaseous fuel: description, characteristics, production methods, application

Gas fuel has been known since the middle of the 19th century. It was then that the famous engineer Lenoir built his first gas internal combustion engine. This apparatus was primitive and worked without pre-compression of the combustion chamber. Modern engines are no match for it. Today, the use of gaseous fuels is not limited to cars. This environmentally friendly, cheap and affordable type of fuel is actively conquering more and more new niches

Gas production. Gas production methods. Gas production in Russia

Natural gas is formed by mixing various gases in the earth's crust. In most cases, the depth of occurrence ranges from several hundred meters to a couple of kilometers. It is worth noting that gas can form at high temperatures and pressures. In this case, there is no access of oxygen to the place. To date, gas production has been implemented in several ways, each of which we will consider in this article. But let's talk about everything in order

Bas alt fabric: description, characteristics, production technology, application

Bas alt fabric: description, characteristics, production technology, application. The first attempts to create bas alt fiber. Countries where the production of bas alt fiber has been established. Properties of bas alt fabric. Products from bas alt fabric

Flow methods of production organization: parameters, characteristics and standards. The need for this method in production

Today, in-line production is the most progressive form of organization of the production system. Optimal speed of work, minimum labor intensity and maximum quality of production - this is not a complete list of the advantages of the method under consideration

Cylinders "Rockwool" (Rockwool): description, device, principle of operation, application, photo

The service life of pipes is reduced due to their use in conditions of low temperatures and high humidity. This problem, however, can be solved by using modern protective materials made of mineral wool. Among the huge variety of proposals on the market, Rockwool cylinders are not the last. The company started its activity more than a century ago in Denmark. During its existence, it has achieved consumer recognition