2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:45

We all deal with metal money every day. Everyone will find coins in their wallet, pocket, piggy bank at home on the shelf. People pay with iron money in stores, at coffee machines and in many other places. But not many people think about how long the historical path the coin has overcome in order to appear before us today in the form in which we are used to seeing it. This article will highlight the main milestones in the development of iron money, and you will also learn how and what coins are made of.

History of coins

The first coins replaced barter commodity relations and "weight" money in the second millennium BC. Metal money of that time, cast in bronze, became the progenitors of the coins that we use now.

Due to the fact that China was an isolated country in those days, the rest of the minted moneythe world learned only in the 7th century BC. At first, the technology was mastered by Asian countries, where it eventually gained popularity, then a new type of money gradually took root in Greece, Rome and a number of other major powers, which subsequently popularized this type of money.

What were the coins made of?

As already mentioned, the first coins were made of bronze, that is, an alloy of tin and copper. The cost of such money was not very high, but it was an established monetary unit that already had a certain weight. In her immediate homeland, in China, this type of money was one of the most popular. However, as time went on, banknotes became more and more popular, and then, in order to increase the value of coins, they began to be cast from precious metals: silver and gold.

And here it is worth mentioning that the work with precious metals at that time was always accompanied by constant doubts, since it was not possible to check the genuine standard of gold and silver. Therefore, in order to once and for all remove the question of what the coins are made of, they began to mark the coats of arms of the state, thereby proving the purity of the material. Such a move with the introduction of expensive metals greatly increased the influence of coins in the states, however, along with gold and silver coins, less expensive ones were also used: copper, bronze, lead and even iron. Of course, their value was very different, in addition, the coin of each individual state differed in its composition.

Similar variety of coins and their value,according to historians, and led to the fact that today we have banknotes of personal denominations, which also differ in value from state to state.

Modern materials

Now the question arises of what alloy modern Russian coins are made of. And this question, alas, cannot be answered unambiguously, since coins of various denominations - a ruble, two rubles, five, ten, as well as coins of 10 and 50 kopecks - are made from different materials. So, for the manufacture of coins in Russia they use steel, cupronickel, nickel, brass, copper and several other additives.

Coin material

- The ruble and two coins are made of chromium steel with nickel plating, which gives the product a characteristic whitish tint. However, until 2009, coins were made from an alloy of nickel and copper.

- The production of coins of 10 rubles is carried out according to a similar principle: steel with a high chromium content and electroplating, but this time from brass.

- Five-ruble coins were previously made by cladding copper with cupronickel. This means that a cupronickel coating was rolled onto the copper base of the coin under pressure and using high temperatures. However, over time, plated coins faded into the background. Nickel-plated money began to be issued, which are generally similar to coins of one and two rubles.

- What are 10 and 50 kopeck coins made of? For a while they were made only from brass, which was expensive, thencladding with brass-copper alloy began to be used, and today brass electroplating is used to produce these coins.

Coin making

Now let's dive into the process. If the question of what coins are made of is over, then the question of how they are made remains open.

Production of a coin, oddly enough, does not begin with metal and the press. First of all, a sketch of the future product is made, and then a detailed plaster mold is created on its basis, on which special attention is paid to small details. Next, this form is placed under a special device, which transfers the pattern from the plaster blank to the metal with high accuracy and on the right scale. After that, minor defects are checked and corrected, and only after that a matrix is produced on the basis of a metal stamp. Next, the matrix is placed in a stamping machine, where pre-cut and polished blanks are fed. The resulting coins are either additionally coated with nickel and polished, or they are given for electroplating and then polished.

Collection coins of Russia

In addition to the already mentioned banknotes, the country's mints make something that only at first glance looks like a simple coin. We are talking about a collectible item for numismatists - collectible coins, which are issued every now and then in honor of some memorable event or date. Their main value lies in the fact that for their manufacture it is oftenreal precious metals are used, they also have a unique appearance and are often produced in extremely limited series, which only increases their value.

Recommended:

Coins of the Soviet Union and modern Russia: what metal are coins made of, their features and varieties

The production of money on the territory of our country at all times was associated with a number of difficulties: the economy either developed or collapsed sharply, dragging faith in the Russian currency to the bottom, giving rise to massive disbelief in it and inflation. Now we have clear state standards for production and minting, all reforms are taking place gradually and accurately, but during the times of revolutions, civil and world wars, the question of what metal coins are made of in our country faded into the background

Heat-resistant alloys. Special steels and alloys. Production and use of heat-resistant alloys

Modern industry cannot be imagined without such material as steel. We encounter it at almost every turn. By introducing various chemical elements into its composition, it is possible to significantly improve the mechanical and operational properties

Production of gas blocks: technological process, materials and equipment

Today, there are many building materials that are popular. One of the innovations is the production of gas blocks, which belong to cellular concrete. Of these, it is profitable not only to build a private house, but also to produce for sale

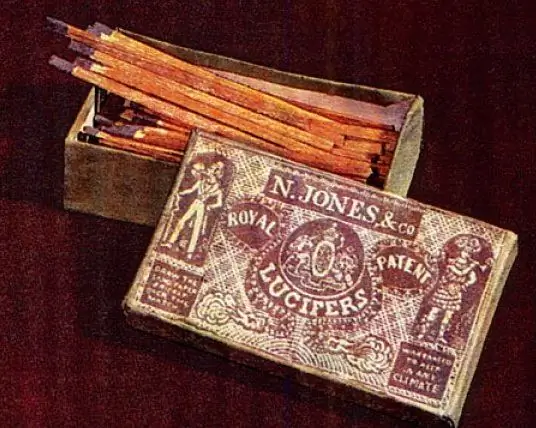

How were matches made before and how are they made today? Swedish matches

The article is devoted to the history of the creation of matches - from their very first prototypes to modern ones. It also tells about the famous Swedish matches, the evolution of the chemical components of the match head and stickers for the box

Restoration of parts by welding and surfacing: methods and methods of restoration, features, technological process

Welding and surfacing technologies allow efficient restoration of metal parts, providing a high degree of reliability and durability of the product. This is confirmed by the practice of using these methods when performing repair operations in a variety of areas - from car repairs to the production of rolled metal. In the total amount of work on the repair of metal structures, the restoration of parts by welding and surfacing takes about 60-70%