2026 Author: Howard Calhoun | calhoun@techconfronts.com. Last modified: 2025-01-24 13:10:37

Today, environmental issues are at the head of the table at almost every meeting of World Governments. It's no secret that ecology has become the new religion of the 21st century. 2017 has been declared the year of environmental protection in Russia, and therefore environmental education is one of the tasks for this year.

Why should water be purified?

Of the total supply of the World Ocean, only 3% is fresh water, of which 68% are glaciers (not suitable for drinking), 30% are underground sources (often polluted from soils) and only 2% are terrestrial sources of water supply. From the global picture of the world it is clear that the availability of clean fresh water is not just a necessity, but sometimes a luxury.

Wastewater generated during economic activitiesenterprises contain a large number of pollutants in concentrations exceeding the permissible and normative ones. As a rule, we are talking about heavy metals (iron, nickel, copper, lead, mercury, cadmium, etc.), petroleum products, suspended solids, aluminum, surfactants (synthetic surfactants, for the layman this is all that foams). These substances, getting into water bodies, disrupt the normal functioning of aquatic biogeocenoses, poison the soil, provoke the growth of blue-green algae, and are toxic to animals. These pollutants are also toxic to humans.

Human activities in residential multi-apartment and private houses also generate a large amount of pollutants. Basically, these are surfactants and organic waste, but metal s alts also get into the sewer.

What is a waste water skimmer?

Floater is a device designed to remove fine impurities from water by a physical and chemical method. Relatively speaking, this is the mechanism of one of the main processing modules in the engineering and technology of wastewater treatment. It is on the flotator that the main separation of dissolved substances and water purification to standard indicators take place.

Industrial skimmers can be designed for both large factories and car washes, differing in size and material.

The main task of the flotator is to isolate and precipitate from the water the pollutants dissolved in it, transferring them intoinsoluble form. This blows air into the appliance to enhance the cleaning effect.

Working principle of wastewater flotation machine

The principle of operation of the flotator is based on passing air bubbles through the medium to be cleaned in order to form foam. This foam is called flotation sludge, which is removed and discharged to special dehydration devices. In order for the bubbles to capture and carry away contaminants, it is necessary to first add special substances - coagulants and flocculants. These substances are highly adhesive, meaning they help pollutants stick to each other and to air bubbles, forming what are called floccules.

The bubble, passing from the nozzle or nozzle of the dispenser to the top, captures sticky contaminants with it. This process is carried out until the water reaches the desired cleaning effect.

The complexity of the process is to accurately select the dose of coagulant and flocculant so that the adhesion force is high enough to stick to the bubble, but the resulting flakes are not too heavy, so as not to damage the air bubble.

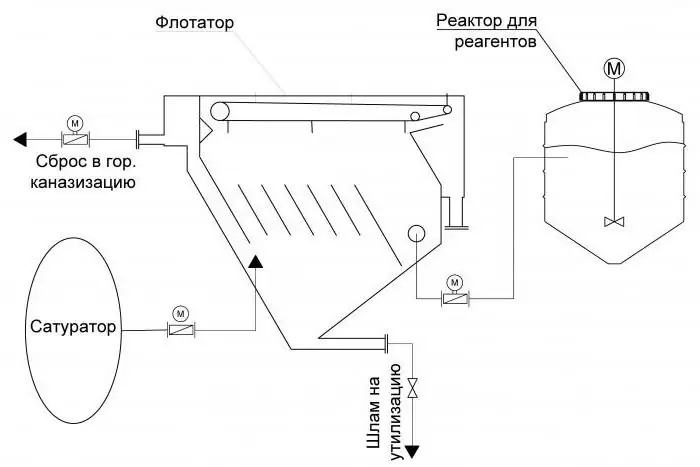

Scheme including a wastewater flotation machine

Technology, which assumes a flotation machine as the main processing module, always includes a reagent farm and an air bubble device. The reagent facility is a container with reagents (coagulants, flocculants, alkali for pH adjustment) and a reactor for mixing the reagent with water.

As a device for creating air bubbles, as a rule, a saturator is used, which is a chamber for mixing air with water in order to create a water-air mixture. This mixture is then sent to the skimmer. The saturation device is equipped with a powerful air pump.

The skimmer is never used separately, it is always included in the overall water purification scheme. The complete scheme, as a rule, consists of the stages of preliminary settling, physical and chemical treatment (flotation or coagulator) and subsequent mechanical cleaning on filters.

In other words, the skimmer cannot provide all cleaning, it is only a separate unit that requires pre-treatment and post-treatment. If sand or other coarse impurities get into the flotator, the device will break down. Also, this device cannot provide disinfection and complete purification from oil products. Therefore, after it, an ultraviolet installation and sorption (or mechanical) filters are needed.

The circuit diagram is based on the flotation process. Flotation is the treatment of waste water with air bubbles in order to extract soluble and emulsified substances. Water enters the main processing module. There, in a pressure (or non-pressure) mode, a pre-prepared reagent is supplied in the reactor. Air bubbles are also fed into the flotator using a saturation device. In the water flotation tank, wastewater is treated with reagents and air bubbles, and moreparts of floccules in the form of flotation sludge. Floating sludge is removed from the surface of the water by a scraper conveyor into the sludge collector.

This sludge is very unstable to mechanical vibrations, so it is collected carefully from the surface of the water in order not to break the foam.

Flotation device

Slootator is an open container made of steel or plastic, equipped with a scraper mechanism for collecting flotation sludge and having a conical shape at the bottom. The flotation tank implies the presence of nozzles in it for supplying an air-water mixture from the saturator, for dumping flotation sludge and emergency emptying, for supplying sewage and discharging treated water. The skimmer installation is usually located at the maintenance site for convenience.

Types of skimmers

Floaters for wastewater treatment are distinguished by how the water is saturated with bubbles and by the nature of the bubbles. The most common methods are mechanical, pressure and electroflotation. Pressure flotation implies the presence of a saturation chamber and a pump group. In addition, reagents are often used in this method. Electroflotation does not need a reagent facility and a saturator, as it is based on the dissolution of electrodes in water.

Mechanical flotation

Mechanical (or impeller) implies the presence of a stirrer, which, at high rotation speed, breaks air bubbles in the water. This type of water treatment is suitable for water prone to foaming and saturated with gases. In the mechanical method, reagents cannot be used, since turbulentthe streams created by the agitator simply break up the flakes of contaminants. At the moment, mechanical flotation is not common, as it rarely provides a sufficient cleaning effect.

As a rule, this treatment segment includes flotation machines for wastewater treatment from oil products.

Pressure flotation

In this case, wastewater treatment flotators are equipped with a saturation device and a reagent facility. The saturator is a chamber in which air is injected at a pressure above atmospheric. The medium prepared in the saturator is called a water-air mixture. This is the most common type of flotation and the most commonly used. The purification process occurs due to the preliminary treatment of water with a reagent (coagulant or flocculant) and subsequent treatment with a pressure of a water-air mixture. Each bubble of gas attaches pollution to itself, as it has a large force of attraction due to the phase boundary (water-air). Pre-treatment of water with a reagent improves cleaning, as it creates floccules (micelles), which also have a certain attraction force. The main part of the water is discharged through the purified water pipe for further treatment or for discharge. From above, a special scraper device removes flotation sludge - contaminants carried upwards with air bubbles in a concentrated form.

The main advantage of pressure flotation is a wide range of applications. The disadvantages include the presence of additional devices (reagent facilities, saturator,pumps) that take up a lot of space and need to be automated (for example, the selection of the dose of reagents). Determining the amount of the reagent plays a big role, since a small dose will lead to insufficient cleaning (not all small dissolved particles will coarsen), and a large dose can lead to the fact that the bubbles will not withstand the weight of the flakes and collapse, which will also lead to a decrease in the cleaning effect.

Electroflotation machine

This type of wastewater flotation machine is characterized by conciseness and ease of operation. The essence of the method lies in the electrolysis of the liquid to be purified and the release of gases from the electrodes. The process of electrolysis takes place in the flotator: hydrogen is released at the cathode, oxygen is released at the anode. When using soluble electrodes (for example, aluminum or iron), water is additionally saturated with metal ions with a high degree of oxidation, which plays the role of reagents for creating flakes of pollution. This process helps isolate and precipitate even more contaminants from the water. Since the space of the skimmer is not large, under such conditions, flakes and air bubbles stick together well, which ensures the highest cleaning effect.

The main advantage of such a device is the absence of reagent facilities and other bulky devices, with a high degree of water purification. Disadvantages include high energy consumption and the need for equipment to remove hydrogen.

Nozzle flotation

In this case, specialnozzles to introduce air into the processed water, which is fed into the skimmer, where it is broken down into a two-phase mixture. The advantage of this method will be less wear of the plant parts, and therefore a longer service life.

Reagent facilities

Some flotation methods use the following reagents to improve the cleaning effect:

- reagents for adjusting pH are acids and alkalis that are added to water to ensure normal working conditions for the coagulant and flocculant;

- coagulants - reagents that promote flocculation and are s alts of iron and aluminum;

- flocculants are reagents that create larger and more stable flakes (flocculi) and are polyacrylamide compounds.

The main disadvantages of having a reagent water treatment method are the need for the presence of personnel, as well as the area that must be allocated for tanks and reactors. It is also very important to choose the right dose of reagents, which is only possible empirically.

Recommended:

Bending machines: types, description, principle of operation

Bending machine: description, specifications, features, principle of operation, photo. Edge bending machines: varieties, device, design, parameters, manufacturers. Manual and rotary hemming machines: what's the difference?

Sewerage: cleaning, removing blockages. Wastewater treatment plant, biological wastewater treatment

The article is devoted to sewer systems and wastewater treatment facilities. Methods for cleaning sewer pipes, biological treatment plants and drainage systems are considered

Water tube boiler: device, principle of operation in industrial energy

Steam generators are mainly used for technological operations - for example, to generate steam by evaporating water. But the possibility of household operation is not excluded, if it is necessary to organize hot water supply for several large consumers. Among the most optimized steam generator designs, one can note the water-tube design. A boiler of this type is not inferior to many analogues in terms of output per unit of time, but its design causes restrictions on operation in cramped conditions

AC machines: device, principle of operation, application

Electric machines perform the critical function of energy conversion in working mechanisms and generating stations. Such devices find their place in different areas, supplying the executive bodies with sufficient power potential. One of the most demanded systems of this type are AC machines (MCT), which have several varieties and differences within their class

Review and rating of industrial washing machines. What are industrial washing machines for laundries

Professional washing machines differ from household models in that in most cases they have higher productivity and other modes, as well as work cycles. Of course, it should be noted that even with the same technical parameters, an industrial model will cost several times more. A little later you will understand why this is so